EricS

Member

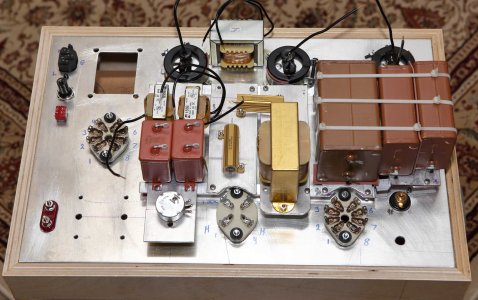

Just one or two more parts to source and I think I'll have everything I need for a full prototype build on an aluminum plate (though, I'm sure I've left *something* out and will have to wait for yet another order to arrive).

Everything is now attached to the base plate except the power and output transformers and I still need to come up with a way to mount the coupling cap between the signal tubes. I'll probably create some sort of metal clamp with a rubber liner and connect it to the mounting screw for the 300B plate choke.

I did a little prep work on the PGP transformer. I gently sanded the laminations and painted it with a gloss black enamel and painted the bell end to make it look like a brass finish. I'll post an image of the transformer when the paint dry. Almost ready to start the wiring.

Everything is now attached to the base plate except the power and output transformers and I still need to come up with a way to mount the coupling cap between the signal tubes. I'll probably create some sort of metal clamp with a rubber liner and connect it to the mounting screw for the 300B plate choke.

I did a little prep work on the PGP transformer. I gently sanded the laminations and painted it with a gloss black enamel and painted the bell end to make it look like a brass finish. I'll post an image of the transformer when the paint dry. Almost ready to start the wiring.