I found the spec sheet (from Freed):

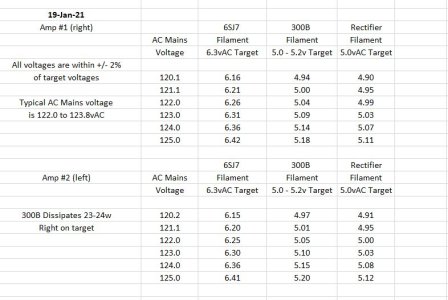

DocB is right, it was wound for 117 volts input; it would be prudent to take 5 to 8 volts off of that; you could likely take those resistors out of the filament/heater lines then. Personally, I'd do it with a homemade autoformer stepdown in its own box, since it would generate less heat than a resistor. You can make one with a 6.3v 2A or greater filament transformer, which should handle both amps.

Temperature rise is specified as 45 to 50 degrees. If room temperature is 20C (68F), that's 65-70C at the transformer, so it's operating within spec though at the limit. For what it's worth, we used it in the pld B-Glow and ParaBee at 70mA and never had any issues.

More ventilation would help, especially getting a little airflow over the 1K cathode resistor. I'd start with 3/8 or 1/2 inch clearance at the bottom - it's easiest.

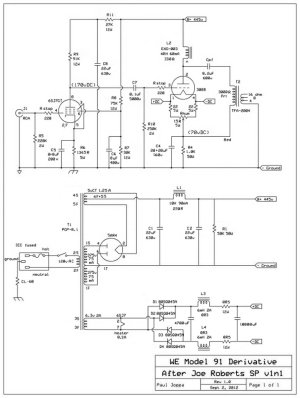

What are you using for a rectifier? The 5v winding is rated 2.0 amps, which is why I specified a 5AR4 rather than the usual 5U4. Actually, the spec sheet suggests a 5Y3, which would give you a bit less B+ but would be easier on the transformer. Other possibilities are 5R4 or 5V4.

It is considered normal to take 3-4 hours for the power transformer to come to final temperature.