L0rdGwyn

New member

Hey PB (and PJ if you happen to stop by  ) ) - still working on my 801A A2 amplifier, still waiting for the Sowter OPT, they are a bit hampered with COVID so I think building is slow, should have them soon.

) ) - still working on my 801A A2 amplifier, still waiting for the Sowter OPT, they are a bit hampered with COVID so I think building is slow, should have them soon.

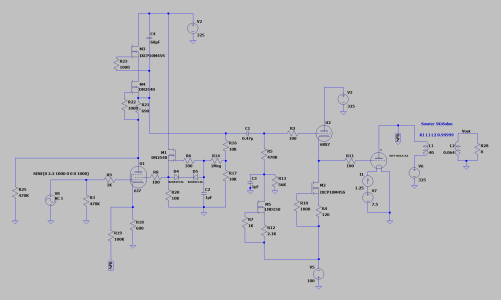

Wanted to show you something pretty cool and also ask if you have any input on something else. I have been hanging around diyAudio and discussing ideas for these high-gain CCS fed pentodes. A certain someone who maintains a certain DIY tube blog suggested a fancier g2 supply for my pentode driver rather than the 1Meg resistor from B+ I was using before. The idea is to use a local feedback mechanism with the DC voltage fed to g2 via FET, with the voltage derived from a divider from the mu output of the CCS. Seems similar ideas are floating around a few places, but the one that inspired the suggestion to me was done by JC Morrison on his transconductance gain block here:

http://www.labjc.com/?p=5317

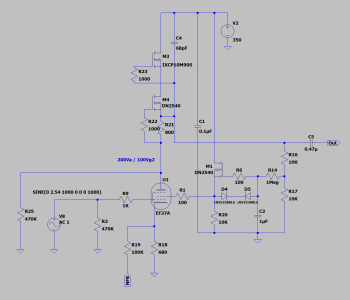

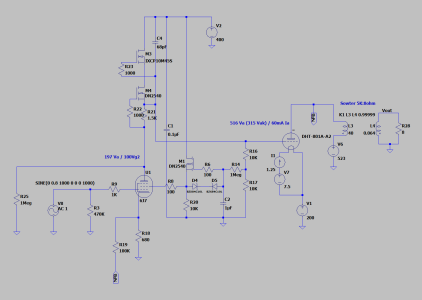

In this arrangement, any drift in the plate voltage is communicated down to the screen, I put together some Spice models, built out the circuit on a protoboard and gave it a shot, schematic below.

What I found is this setup provides VERY stable anode / screen voltages. At maximum output into a 8ohm dummy load, sine waves as well as real music, I never see a voltage drift more than 0.5V on either, pretty nice, so this is going in the final design. With the exact setup I have shown below, I am getting 0.14% THD at 1W out of the amplifier.

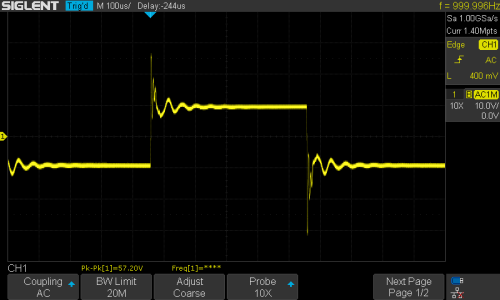

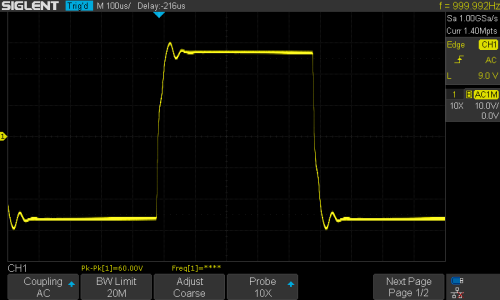

This design is 95% of the way there, just a matter of dialing in the feedback / output impedance / FR / harmonic profile when the Sowter stuff gets here. The only niggling thing left is some somewhat ugly overshoot / ringing I am seeing on square waves, shown below as well, the output from the EF37A. The amplifier is stable, perhaps it is a non-issue or will resolve with the Sowter OPT, still need to do some more troubleshooting, but the Lundahls seem quite prone to this type of ringing, we will see.

Stay safe fellas! Hopefully 2021 is a better year.

Wanted to show you something pretty cool and also ask if you have any input on something else. I have been hanging around diyAudio and discussing ideas for these high-gain CCS fed pentodes. A certain someone who maintains a certain DIY tube blog suggested a fancier g2 supply for my pentode driver rather than the 1Meg resistor from B+ I was using before. The idea is to use a local feedback mechanism with the DC voltage fed to g2 via FET, with the voltage derived from a divider from the mu output of the CCS. Seems similar ideas are floating around a few places, but the one that inspired the suggestion to me was done by JC Morrison on his transconductance gain block here:

http://www.labjc.com/?p=5317

In this arrangement, any drift in the plate voltage is communicated down to the screen, I put together some Spice models, built out the circuit on a protoboard and gave it a shot, schematic below.

What I found is this setup provides VERY stable anode / screen voltages. At maximum output into a 8ohm dummy load, sine waves as well as real music, I never see a voltage drift more than 0.5V on either, pretty nice, so this is going in the final design. With the exact setup I have shown below, I am getting 0.14% THD at 1W out of the amplifier.

This design is 95% of the way there, just a matter of dialing in the feedback / output impedance / FR / harmonic profile when the Sowter stuff gets here. The only niggling thing left is some somewhat ugly overshoot / ringing I am seeing on square waves, shown below as well, the output from the EF37A. The amplifier is stable, perhaps it is a non-issue or will resolve with the Sowter OPT, still need to do some more troubleshooting, but the Lundahls seem quite prone to this type of ringing, we will see.

Stay safe fellas! Hopefully 2021 is a better year.