Yeah, that was totally non-intuitive for me: any old 1/4w resistor will work for this application! It's my strong desire for way over-engineering things that pushed me toward a 3w part for this purpose.

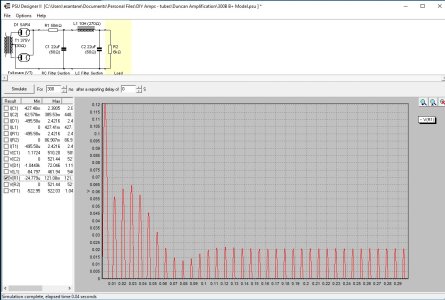

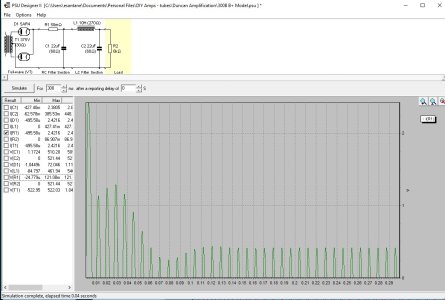

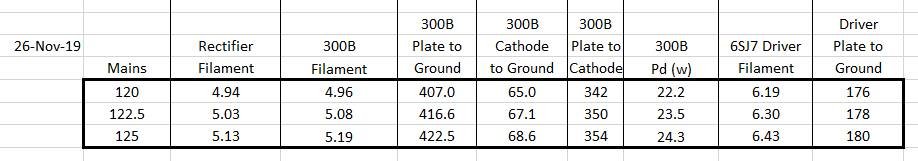

The pair of 0R5 Mills MRA12 wirewound resistors that I put on the 300B filament to tame the voltage get toasty warm at 60c. 1.5A of current pass through those guys, so they dissipate about 1.125w of power each. Derating for temp, they're still good for 75% of their rated power at 100c, so things should be good here. The 300B filament PSU is a CLCR (1,000uF, Hammond 155B, 10,000uF, then 0R5) and I keep wondering whether the better solution is to torture the resistors at the end or torture a smaller first cap in order to hit a 5.0-5.1v target. Using the CLCR approach, ripple on the heater is about 9mV - this wasn't really my goal, but is a nice side effect of clamping down on the voltage.