EricS

Member

Understood - I agree that exceeding current ratings can end in all sorts of bad outcomes that are best avoided. I tend to be a fan of the Nelson Pass approach to (over)engineering circuit designs: Wear both a belt and suspenders. I can arc-weld with the PSU of my 150w Class A solid state amps

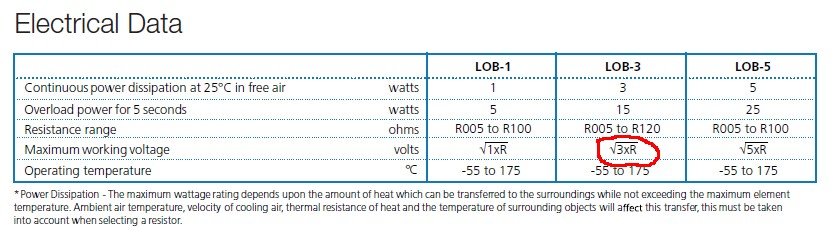

Is there a compelling reason not to add series resistance to trim the rest of the AC voltage on the filament? I've been doing lots of searching/reading and haven't found anyone saying that this is a bad idea...

Is there a compelling reason not to add series resistance to trim the rest of the AC voltage on the filament? I've been doing lots of searching/reading and haven't found anyone saying that this is a bad idea...