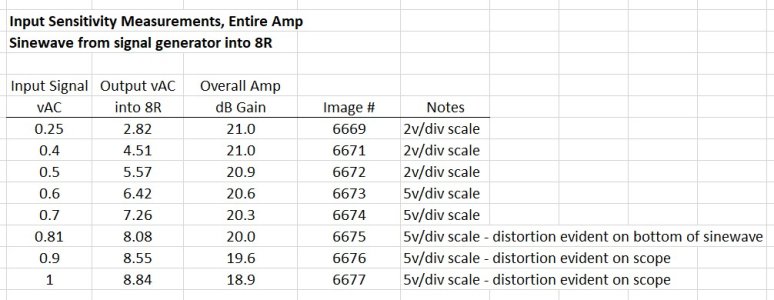

I spent some time making measurements with some meters, a signal generator, and scope with the hopes that someone can either guide me toward making a change to elevate the driver cathode/adjust the plate voltage to the intended voltage, or just leave it alone and start enjoying the amp. Overall, the amp with the PSVane 300B tube can drive about 8v into an 8R load with an input signal of 0.8vAC before distortion becomes evident on the scope.

Here is a description of the tables I've attached:

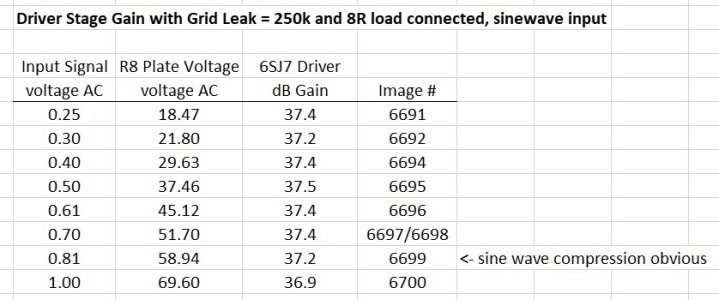

The first attached chart is gain measurements of the 6SJ7GT driver stage, measured at the "input side" of the coupling cap with an 8R load attached. Looks pretty constant at about 37dB of gain for the first stage. Don't know if this is where it is supposed to be or not...

The second chart is the overall gain of the entire amplifier into an 8R load as well as input signal level sensitivity. Overall gain for the entire amp into an 8R load looks pretty constant at about 21dB. This seems a little low to me, I was expecting somewhere closer to 27dB based on some comments PJ posted some time ago on another forum. It also took close to 0.75vAC input in order for the amp to reach maximum clean output on the scope. PJ's prior posting also indicated an input sensitivity of about 0.35vAC, so this figure looks a little "off" to me...

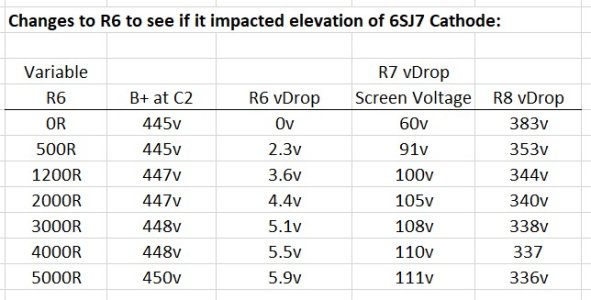

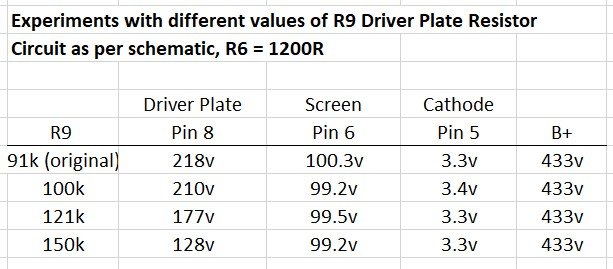

The third chart is an experiment with different values of the Driver Plate Resistor R9. I didn't know how safe this experiment would be, so I only powered up the amp briefly enough for the B+ to stabilize and make a reading, then I shut it down. Changing R9 seemed only to impact the plate voltage and didn't do much to the cathode elevation.

I also swapped out R10 for one of Mike's BPC-16 Ni chokes. As PB predicted, this was a bad idea. It both introduced noise (hum pickup) and absolutely KILLED the bandwidth of the amp. With R10 set to 250k as per the schematic, the point at which output magnitude was reduced to 70% relative to the magnitude of a 1kHz sine wave is about 22kHz (this seems a bit low to me - I was expecting a tube amp to be somewhere near 200kHz bandwidth, but perhaps I am wrong here). When R10 was replaced with the grid choke, the 70% output mark happened at 10kHz! I put the 250k resistor back in.

I also have images from the scope for all of these readings. I figured I didn't need to post 50 images until someone asked for something specific...

So, is there tweaking to do to adjust plate/cathode voltage levels? A few of these readings seem to deviate from my expectations...