theirishscion

New member

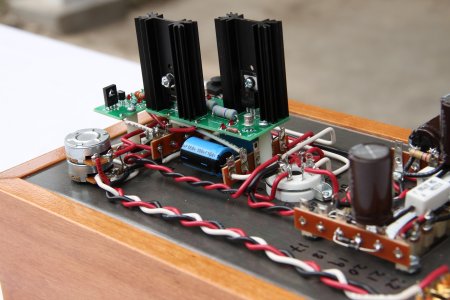

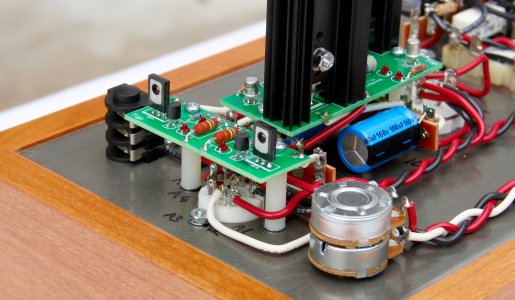

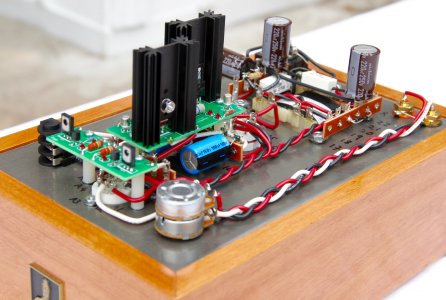

Not really notable in any way. I did try to do slightly pretty wires. Also I shot the brushed plate (and the transformer bell) with three coats of clear to make it a bit easier to keep looking nice. Highly recommended tweak, that.

Lovely relaxing build. I was slightly naughty and did it such that the components that the speedball replaces were just tacked on to the terminals for testing purposes so I didn't have to leave cut wires behind (or bork two perfectly useful 5w power resistors)

(I tried to put the images on imgur to save the Bottlehead the bandwidth/disk space. No go, you get to suffer them here instead)

Lovely relaxing build. I was slightly naughty and did it such that the components that the speedball replaces were just tacked on to the terminals for testing purposes so I didn't have to leave cut wires behind (or bork two perfectly useful 5w power resistors)

(I tried to put the images on imgur to save the Bottlehead the bandwidth/disk space. No go, you get to suffer them here instead)

Attachments

-

IMG_0047.jpg1.5 MB · Views: 262

IMG_0047.jpg1.5 MB · Views: 262 -

IMG_0075.jpg2.1 MB · Views: 293

IMG_0075.jpg2.1 MB · Views: 293 -

IMG_0074.jpg1.2 MB · Views: 151

IMG_0074.jpg1.2 MB · Views: 151 -

IMG_0072.jpg2.4 MB · Views: 273

IMG_0072.jpg2.4 MB · Views: 273 -

IMG_0068.jpg2.1 MB · Views: 214

IMG_0068.jpg2.1 MB · Views: 214 -

IMG_0066.jpg1.5 MB · Views: 248

IMG_0066.jpg1.5 MB · Views: 248 -

IMG_0065.jpg1.9 MB · Views: 284

IMG_0065.jpg1.9 MB · Views: 284 -

IMG_0059.jpg2.5 MB · Views: 117

IMG_0059.jpg2.5 MB · Views: 117 -

IMG_0056.jpg3.6 MB · Views: 111

IMG_0056.jpg3.6 MB · Views: 111 -

IMG_0052.jpg2.7 MB · Views: 155

IMG_0052.jpg2.7 MB · Views: 155 -

IMG_0051.jpg2.2 MB · Views: 163

IMG_0051.jpg2.2 MB · Views: 163 -

IMG_0049.jpg2.5 MB · Views: 189

IMG_0049.jpg2.5 MB · Views: 189