You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Crack Build - First Headphone amp build

- Thread starter Urshurak776

- Start date

hmbscott

Member

I have been baking my chassis in the oven at 160-180F for about an hour. It accelerates setting, increases gloss, and makes the paint harder. I've been using Rustoleum Hammered with that bake. The paint is still not instantly fully hard, and so I give it another week at least before building.

For single part enamel like that, letting it dry for two weeks is a very good idea.

Urshurak776

Member

Thanks guys. I thought about the oven, but my wife would probably kill me. Lol. Plus, I still have the IEC connector and switch installed. No way those are coming out without breaking them. Super tight fit.

I’ll just wait a couple weeks.

I’ll just wait a couple weeks.

Last edited:

Those will come out if you put them in the oven.

Natural Sound

Active member

FWIW I always let Rustoleum hammered finish paint sit for AT LEAST 2 weeks. Usually more. Its great paint, I use it all the time. But it takes forever to harden up fully. I thought about using the oven method but my wife would kill me.  So I wait patiently and sometimes place the painted parts in a sunny window.

So I wait patiently and sometimes place the painted parts in a sunny window.

The Crack amp is a very good design and sounds great. I picked up a kit from the first run many years ago. I'm thinking around 2010? It's still running strong on my computer desk. You'll love it.

The Crack amp is a very good design and sounds great. I picked up a kit from the first run many years ago. I'm thinking around 2010? It's still running strong on my computer desk. You'll love it.

Urshurak776

Member

The oven thing isn't in the cards for me, so I just have it in my home office hanging out for a couple weeks. It's tough because I want to build it!

Bear

New member

Feel for you. I can imagine the frustration.So, disappointed in myself for my carelessness. Not only did I slip with the wrench tightening the potentiometer, but I then DROPPED the wrench right on the chassis....

Taking everything off except the IEC connector (no freaking way that’s coming off…it was TIGHT getting it to snap in.) I'll put blue painters tape around it.

Hitting it with more paint here shortly, then have to wait a few more days to cure. To be honest, I'm not sure I let it cure long enough anyway. I would think that 6 full days in my 68 degree office would be enough, but maybe not?

Sigh…..

Urshurak776

Member

Thanks Bear. It reminded me to sloooow down.Feel for you. I can imagine the frustration.

I may have missed it in your thread, but what tubes are you running?

Bear

New member

The stock 6080 and 12AU7 that came in the box.Thanks Bear. It reminded me to sloooow down.

I may have missed it in your thread, but what tubes are you running?

I have some Ray Tubes and Electro Harmonix gold pin 12AU7’s from my Apos Gremlin I can roll down the line, but more than happy with the current valves. Will want to be very familiar with the Crack before I start tube rolling.

Urshurak776

Member

Nice. My crack came with a JAN (joint army-navy) 6080. Looks brand new. The 12AU7 is a Motorola. I have a Mullard also that I got from a friend when we were playing with a Fender 5E3 tube amp. That amp uses a 12AX7, so the gain was too low. I also got a Russian tube (winged ‘C’ or something like that) that seems to be well regarded in the crack. Looks like a big coke bottle. Really cool looking.The stock 6080 and 12AU7 that came in the box.

I have some Ray Tubes and Electro Harmonix gold pin 12AU7’s from my Apos Gremlin I can roll down the line, but more than happy with the current valves. Will want to be very familiar with the Crack before I start tube rolling.

Looking at getting a DAP also. The one you have is nice but I can’t do $600 right now. Looking for a $200 or so option, if that even exists…

Bear

New member

I got the same 6080 but I can’t see any identifier on the 12AU7.Nice. My crack came with a JAN (joint army-navy) 6080. Looks brand new. The 12AU7 is a Motorola. I have a Mullard also that I got from a friend when we were playing with a Fender 5E3 tube amp. That amp uses a 12AX7, so the gain was too low. I also got a Russian tube (winged ‘C’ or something like that) that seems to be well regarded in the crack. Looks like a big coke bottle. Really cool looking.

Looking at getting a DAP also. The one you have is nice but I can’t do $600 right now. Looking for a $200 or so option, if that even exists…

When I got the iBasso DX180 I was torn between it and the Hiby R4 which is USD249 I believe and is currently on sale at my local retailer in Australia so if it’s a global thing there may be discounts in your neck of the woods too. Tempted by the R4 at the reduced price.

The R4 sounds great and has excellent system wide EQ including the Magic Eight Ball or whatever it’s called proprietary slider system. Only swayed by the iBasso as it runs cooler and is marginally more refined.

Urshurak776

Member

I’ll check out the R4! Thanks!I got the same 6080 but I can’t see any identifier on the 12AU7.

When I got the iBasso DX180 I was torn between it and the Hiby R4 which is USD249 I believe and is currently on sale at my local retailer in Australia so if it’s a global thing there may be discounts in your neck of the woods too. Tempted by the R4 at the reduced price.

The R4 sounds great and has excellent system wide EQ including the Magic Eight Ball or whatever it’s called proprietary slider system. Only swayed by the iBasso as it runs cooler and is marginally more refined.

Urshurak776

Member

So, chomping at the bit to get this thing built. Tomorrow is 3 weeks that the chassis paint has been curing. Build will start either Friday or Saturday. That should give me 3 weeks and 4 days. Seems nice and hard now. I can't push a fingernail into it anymore.

bucketofguts

Member

Well I could not wait to build mine and after Volvo touch-up spray can , clear coat and listening to mine the finished cracked and looks like a 1960's guitar finish I think looks very cool.More power to your patience. Good luck with the rest of your build.

Urshurak776

Member

Urshurak776

Member

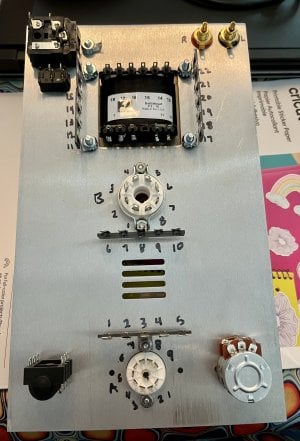

Quick question. I am installing the two diodes between the IEC ground tab and the safety ground in the chassis. I plan to use USB DAC so figured it was worth while. Is this acceptable to do it this way, and just have the one lead in each terminal? I have not soldered anything yet, but the pic shows what I mean.

Attachments

Yes, you might also find that it helps to take your needle nose pliers and push those wraps up against the diode body so there's more thin lead available to slide into the holes to get those into position.