Hi all, I posted about this before, but for some reason, the website is giving me a hard time replying and updating, so I decided to post again with more details.

Like the title says, just finished building the crack. I checked the resistance this morning and the numbers all matched the manual's.

Last night I was performing the voltage test with tubes installed. The 12u7 tube glows with no issue but the 6080 doesn't glow at all. The LED's were on for five minutes, but then they turned off and hasn't turned back on since.

The voltage also seems to be pretty low compared to what the manual says. Also worth noting that I checked the orientation of the 8 pin socket and it's pointing towards the vent holes as instructed. As for the L+N voltage test, my meter measured 121v, so I followed the instructions on page 25

1- 2.30v

2- 2.30v

3- 0v

4-2.3v

5-2.3v

6-0v

7-0v

8-0v

9-0v

10-0v

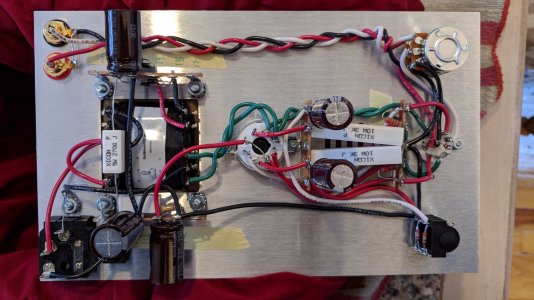

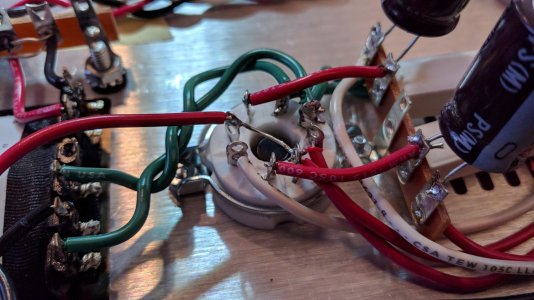

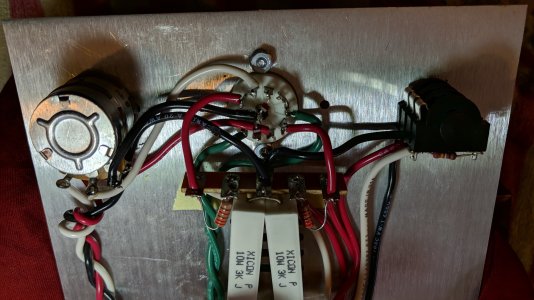

Also added photos below.

Thanks

Like the title says, just finished building the crack. I checked the resistance this morning and the numbers all matched the manual's.

Last night I was performing the voltage test with tubes installed. The 12u7 tube glows with no issue but the 6080 doesn't glow at all. The LED's were on for five minutes, but then they turned off and hasn't turned back on since.

The voltage also seems to be pretty low compared to what the manual says. Also worth noting that I checked the orientation of the 8 pin socket and it's pointing towards the vent holes as instructed. As for the L+N voltage test, my meter measured 121v, so I followed the instructions on page 25

1- 2.30v

2- 2.30v

3- 0v

4-2.3v

5-2.3v

6-0v

7-0v

8-0v

9-0v

10-0v

Also added photos below.

Thanks