Dang it, yeah I meant electronics store.

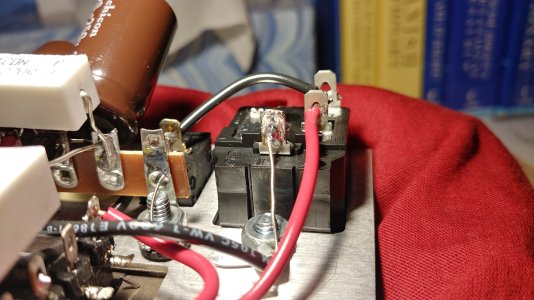

I measured the 7 and 8 pins on the tube and got a resistance around 1 ohms.

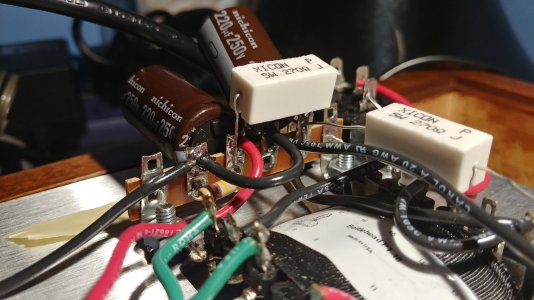

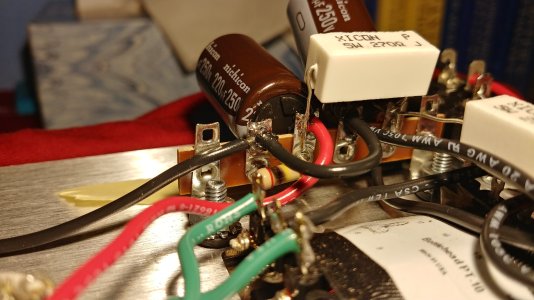

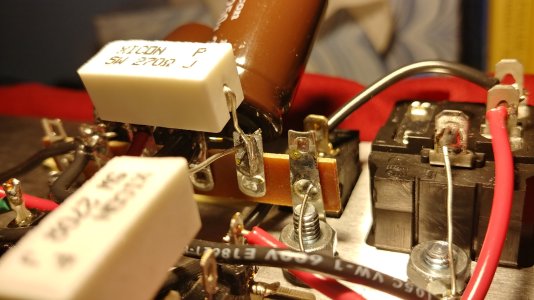

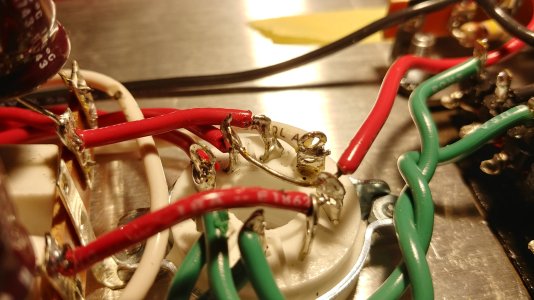

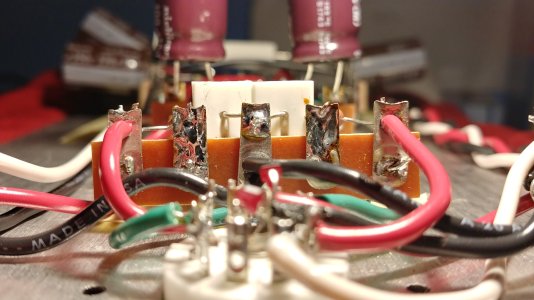

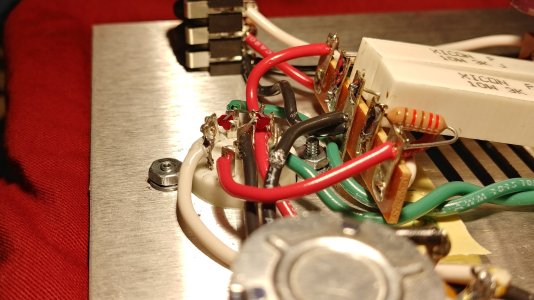

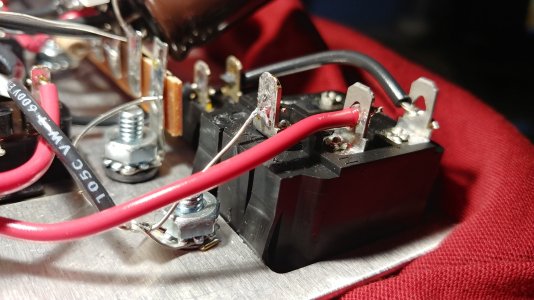

My dad was testing the voltages and resistance using the schematic, and the only issue he found so far was that dead 270ohm resistor. Right now, I'm going to look for any weak soldering joints, weak resistor probe connections, voltages, sawdust etc. Is there anything else I should look for in the mean time? Do the probes have to be completely through the hole on the terminals if it's connected by solder?

I measured the 7 and 8 pins on the tube and got a resistance around 1 ohms.

My dad was testing the voltages and resistance using the schematic, and the only issue he found so far was that dead 270ohm resistor. Right now, I'm going to look for any weak soldering joints, weak resistor probe connections, voltages, sawdust etc. Is there anything else I should look for in the mean time? Do the probes have to be completely through the hole on the terminals if it's connected by solder?