Hello!

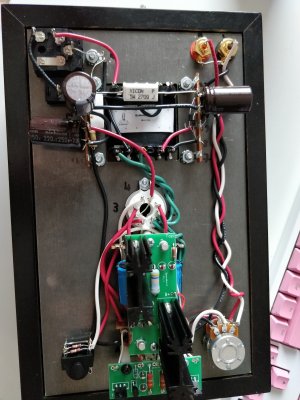

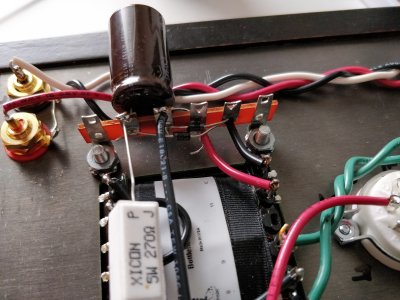

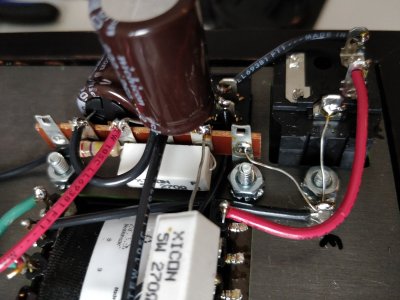

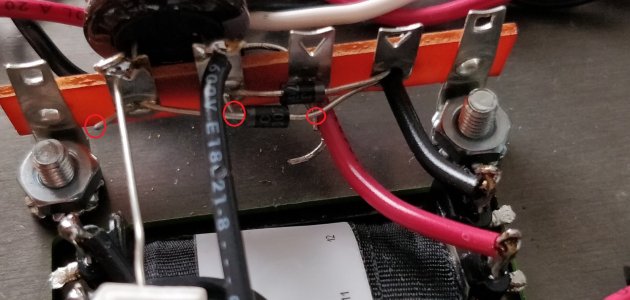

I finished the crack around a week ago. I absolutely love it. My problem is that after a few days of listening a slight cracking sound appeared on the right channel. I have re-soldered all the connections, and there were some bad ones on 3L, 1L, the grounding point near the power inlet and the 2 black wire meeting point on the headphone jack.

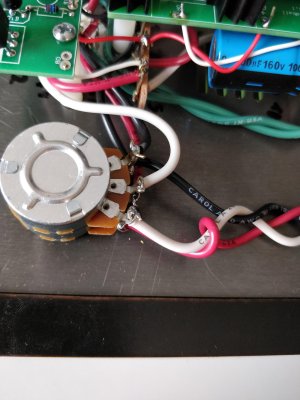

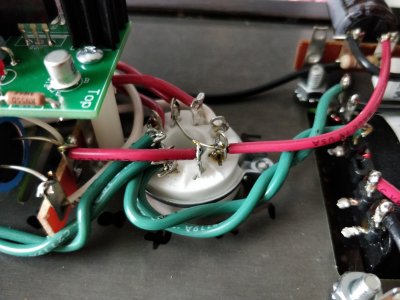

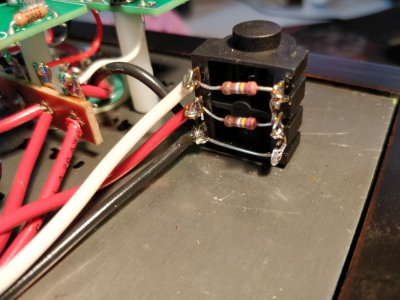

At first I thought I solved the issue when I soldered the grounding jack and I didnt hear the crackling anymore. I then added the speedball but the noice was there again. Then I left the amp on for 8 hours, and when I woke up the sound was a lot louder than before, it was very prominent. I had to go to work so didnt have time to chopstick it at the time. Then after the amp had been on continously for 16 hours there was no noise again when I was starting to debug it. I wait for a couple of hours and its there again but its very silent and it comes and goes so its hard to test what connection might be making the sound. Only time something changed when I was poking the connections, was when I found the loose connection on the headphone jack. I tried to scotchbrite the 12au7 pins but that didnt help either. I ordered a new 12au7 to see if it helps. Sometimes the crackling varies when I poke the 12au7 and sometimes it doesnt so I dont know if that is the cause or not. I have gone over the solderings over so many times now that I dont know where to go with that. Any tips on certain points I should re-check one more time?

Also the crackling doesnt happen right after I turn on the amp but it comes and goes after the amp has been warming for a while. Volume pot position doesnt affect the intensity of the sound.

Thanks for any tips.

edit.// To add I'm using Computer->R2R-11 dac output->Crack->HD600. I have tried it with a different cable to the HD600 and with G4me zero senn gaming headset and the same thing happens. The sound was first coming from the left channel, but im pretty sure that I didnt have the hd600 connected the right way when I first used it. IT would be weird for the sound to jump to other channel after some re-soldering wouldnt it?

I finished the crack around a week ago. I absolutely love it. My problem is that after a few days of listening a slight cracking sound appeared on the right channel. I have re-soldered all the connections, and there were some bad ones on 3L, 1L, the grounding point near the power inlet and the 2 black wire meeting point on the headphone jack.

At first I thought I solved the issue when I soldered the grounding jack and I didnt hear the crackling anymore. I then added the speedball but the noice was there again. Then I left the amp on for 8 hours, and when I woke up the sound was a lot louder than before, it was very prominent. I had to go to work so didnt have time to chopstick it at the time. Then after the amp had been on continously for 16 hours there was no noise again when I was starting to debug it. I wait for a couple of hours and its there again but its very silent and it comes and goes so its hard to test what connection might be making the sound. Only time something changed when I was poking the connections, was when I found the loose connection on the headphone jack. I tried to scotchbrite the 12au7 pins but that didnt help either. I ordered a new 12au7 to see if it helps. Sometimes the crackling varies when I poke the 12au7 and sometimes it doesnt so I dont know if that is the cause or not. I have gone over the solderings over so many times now that I dont know where to go with that. Any tips on certain points I should re-check one more time?

Also the crackling doesnt happen right after I turn on the amp but it comes and goes after the amp has been warming for a while. Volume pot position doesnt affect the intensity of the sound.

Thanks for any tips.

edit.// To add I'm using Computer->R2R-11 dac output->Crack->HD600. I have tried it with a different cable to the HD600 and with G4me zero senn gaming headset and the same thing happens. The sound was first coming from the left channel, but im pretty sure that I didnt have the hd600 connected the right way when I first used it. IT would be weird for the sound to jump to other channel after some re-soldering wouldnt it?