You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hum and no audio

- Thread starter ryburdman

- Start date

The last Reduction I fixed had the following issues:

1. All the RCA jacks were not installed properly. The metal ring tab was mounted against the chassis and not directly under the nut, which caused there to be no audio.

2. The ground wires that run through/around the 9 pin sockets were loose on the sockets and not adequately soldered.

3. There were a few other random solder joints that weren't solid that were also causing problems.

Since you don't have audio on either channel, I would be looking at how you installed your RCA jacks.

1. All the RCA jacks were not installed properly. The metal ring tab was mounted against the chassis and not directly under the nut, which caused there to be no audio.

2. The ground wires that run through/around the 9 pin sockets were loose on the sockets and not adequately soldered.

3. There were a few other random solder joints that weren't solid that were also causing problems.

Since you don't have audio on either channel, I would be looking at how you installed your RCA jacks.

Can you post some build photos?

If the RCA jacks are assembled in the proper order, then the problem you have suggests there's a loose solder joint or two.

If the RCA jacks are assembled in the proper order, then the problem you have suggests there's a loose solder joint or two.

I would recommend getting a proper pair of side cutters (I use the CHP-170) and trim off all those leads nice and short that are poking out. The one coming out of 26L that's almost touching the chassis will smoke part of the amp when it does touch the chassis.

I would reheat the solder joints on the ground lug of each input RCA jack. Those don't look like they have flowed out all the way.

I would reheat the solder joints on the ground lug of each input RCA jack. Those don't look like they have flowed out all the way.

Yeah and maybe reflow terminal 22. Can't see it in the pics, but that is what the ground end of the output RCA connects to. RE the side cutters, I just got a pile of grievance for not buying $40 swiss side cutters when I posted my intended-to-be-humorous broken sidecutter on social media. A Swiss sidecutter that, I will note, won't fit into a lot of tight places we need side cutters to fit. I would guess the guys posting the spendy cutters don't work in an environment where the less experienced employee will use a soldering iron for a prybar or a ceramic screwdriver as a cold chisel. I lost a really nice $500 solder station to that kind of activity. The $5 side cutters like Hakko and Xcelite we have around are perfectly adequate for what we are doing and it's no biggie if somebody does something dumb with them. We cut thousands of pieces of wire with those cutters every year.

D

Deke609

Guest

My two cents: I wouldn't even try to hunt down the problem until I reheated every single solder joint in the amp. I see a lot of what look to be cold solder joints (lumpy solder) and no signs of melted wire insulation near the cut ends -- both signs of using too low a temperature. If you have an adjustable iron, I'd crank it up to at least 750 F. If you don't have an adjustable iron, try letting the tip dwell longer on the joint. When reheating a joint, it's not enough that the solder melts; you want to see it run like water into the joint. MORE HEAT! You might find that reheating all the joints solves the problem a lot faster than trying to figure out which particular joint or joints is/are the problem -- and end up with a amp that will stay sounding great longer.

cheers from the peanut gallery, Derek

cheers from the peanut gallery, Derek

I set mine at 899, which is as high as it can go.

If you happen to have new Hakko 888, it's very easy to think you're turning up the heat when you are actually in calibration mode and are in actuality decreasing what would be the maximum temperature.

If you happen to have new Hakko 888, it's very easy to think you're turning up the heat when you are actually in calibration mode and are in actuality decreasing what would be the maximum temperature.

Recheck your voltages and resistances.

44 and 45 will depend a bit on the meter, but if everything else is OK those terminals can't be incorrect.

I would suggest that you're still looking at a bad solder joint or a solder bridge across an RCA jack. You could certainly post some more photos, especially since you can now focus in on one half of the build.

I would suggest that you're still looking at a bad solder joint or a solder bridge across an RCA jack. You could certainly post some more photos, especially since you can now focus in on one half of the build.

Can you remove the inner lead of the 0.1uF coupling cap and the 0.47uF coupling cap and pull them straight up, then post some more pics with those mostly out of the way?

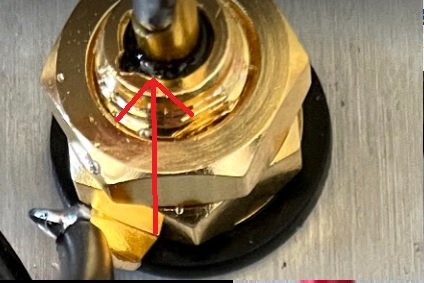

This could also cause problems. This and solder joints is the kind of stuff you want to look for when your DC voltages look good but sound isn't making it through.

If cleaning out these jacks doesn't work, let me know what kind of multimeter you have (brand and model) and we can send some signal voltage into your Reduction and take some measurements.

If cleaning out these jacks doesn't work, let me know what kind of multimeter you have (brand and model) and we can send some signal voltage into your Reduction and take some measurements.

Attachments

Similar threads

- Replies

- 34

- Views

- 16K