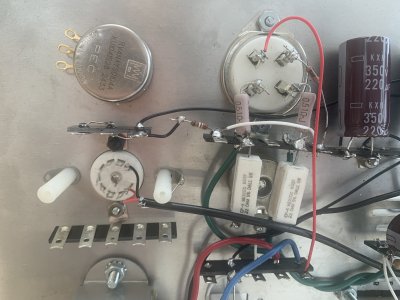

Kaiju Assembly Probelms

I seems to have hit a problem where I need your help: I completed up until page 46 (European A4 formatting, and went on to the testing of the “High Voltage Power Supply Test”. The results were.

w/o tubes

10U: 237V discharging after the test to -18V

14U: 486V discharging to 0V

15U: 234V discharging to-15V

With tubes

53U: 66V

65U: 219V

The last measurement is the problem. I added the other for info to give you further info.

I have:

Gone through the assembly process from page 1-47 and checked all step virtually

I have measured “across” all solderings to check for connection (0ohm on the DMM)

Visually inspected the assembly under a magnifying glass and found no errors

I can also add the I measured all resistors to verify identification before assembly

Capacitors and transformers were not measured

Can you help me out based on above or do you need more information.

How do I identify faulty components after assembly - all ideas are welcome

Best regards Pete

I seems to have hit a problem where I need your help: I completed up until page 46 (European A4 formatting, and went on to the testing of the “High Voltage Power Supply Test”. The results were.

w/o tubes

10U: 237V discharging after the test to -18V

14U: 486V discharging to 0V

15U: 234V discharging to-15V

With tubes

53U: 66V

65U: 219V

The last measurement is the problem. I added the other for info to give you further info.

I have:

Gone through the assembly process from page 1-47 and checked all step virtually

I have measured “across” all solderings to check for connection (0ohm on the DMM)

Visually inspected the assembly under a magnifying glass and found no errors

I can also add the I measured all resistors to verify identification before assembly

Capacitors and transformers were not measured

Can you help me out based on above or do you need more information.

How do I identify faulty components after assembly - all ideas are welcome

Best regards Pete