Thank you Paul and grufti.

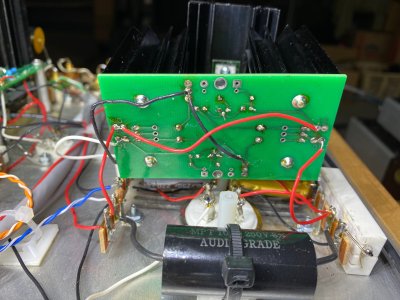

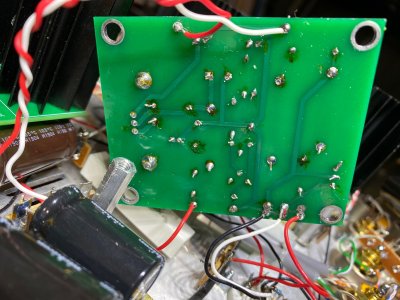

The joint missing solder on the back of the B side filament board was actually soldered from the top, but I soldered it from below just now as well.

Thank you for spotting that.

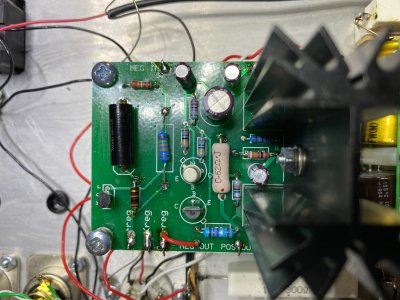

The B-side LEDs are all still out, all four of them now, and the voltage at termnial 12 is 0.04V.

The A-side LEDs all come on, but then go out at the same time after ten minutes of power on.

The solderer is a 63 year-old man with vision impaired by a central retinal vessel occlusion in the left eye, not too proud to use magnification and loupes and direct overhead light.

Iron is a Hakko 936 usually set at 850F on the Hakko dial.

Soldering tip is a 1.5 mm "D" wedge, Hakko brand.

Tip cleaning with Hakko brass wool and a wet sponge.

Solder is Cardas quad eutectic flux core.

Copper wick method used to remove solder when necessary.

Knipex cutter used for wire cutting, stripping.

Appreciate your help,

Mark

The joint missing solder on the back of the B side filament board was actually soldered from the top, but I soldered it from below just now as well.

Thank you for spotting that.

The B-side LEDs are all still out, all four of them now, and the voltage at termnial 12 is 0.04V.

The A-side LEDs all come on, but then go out at the same time after ten minutes of power on.

The solderer is a 63 year-old man with vision impaired by a central retinal vessel occlusion in the left eye, not too proud to use magnification and loupes and direct overhead light.

Iron is a Hakko 936 usually set at 850F on the Hakko dial.

Soldering tip is a 1.5 mm "D" wedge, Hakko brand.

Tip cleaning with Hakko brass wool and a wet sponge.

Solder is Cardas quad eutectic flux core.

Copper wick method used to remove solder when necessary.

Knipex cutter used for wire cutting, stripping.

Appreciate your help,

Mark