Hi,

I have been reading this forum for a few months and have found it to be a great resource as well as fun to read. My kit arrived about a week ago and I have started working on it. Briefly, I have no experience working on electronics, never have used a soldering iron before and have no woodworking skills to speak of.

However, building my own amplifier was so intriguing that I just had to try. Another disclaimer is that I am well aware that I should be building the original kit but I just could not resist making some substitutions that I have seen mentioned frequently on the forum. Clearly, I am not blaming anybody else particularly when, as possible, I come back for troubleshooting help.

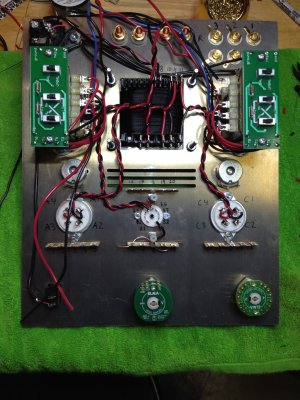

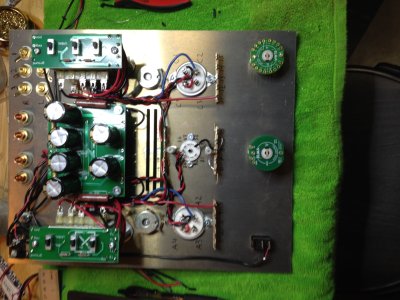

So my upgrades include:

goldpoint selector and stepped attenuator

cardas speaker binding posts

Mundorf coupling, parafeed caps

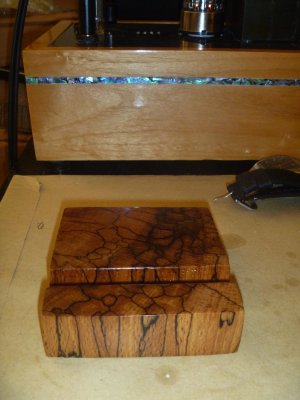

My main issue so far has been, unexpectedly, the finishing of the woodbase. I didn't like the streaky polyurethane finish, so I ended up sanding it down again and starting over.

I hope the images download correctly. If not, I may need some help.

Boris

I have been reading this forum for a few months and have found it to be a great resource as well as fun to read. My kit arrived about a week ago and I have started working on it. Briefly, I have no experience working on electronics, never have used a soldering iron before and have no woodworking skills to speak of.

However, building my own amplifier was so intriguing that I just had to try. Another disclaimer is that I am well aware that I should be building the original kit but I just could not resist making some substitutions that I have seen mentioned frequently on the forum. Clearly, I am not blaming anybody else particularly when, as possible, I come back for troubleshooting help.

So my upgrades include:

goldpoint selector and stepped attenuator

cardas speaker binding posts

Mundorf coupling, parafeed caps

My main issue so far has been, unexpectedly, the finishing of the woodbase. I didn't like the streaky polyurethane finish, so I ended up sanding it down again and starting over.

I hope the images download correctly. If not, I may need some help.

Boris