I've been having some peculiar vacuum tube adventures lately. I'd appreciate thoughts and insights on this.

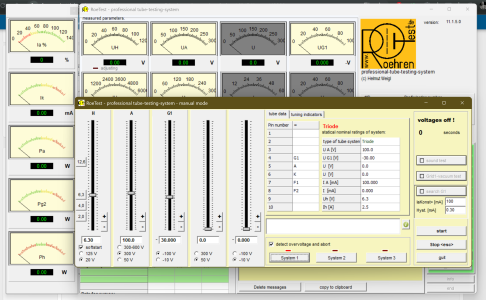

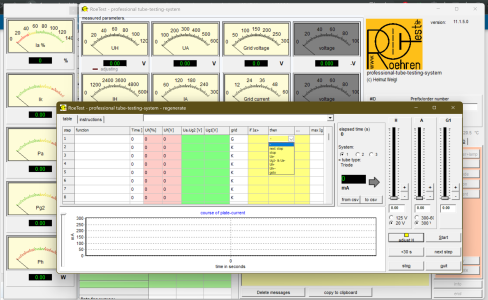

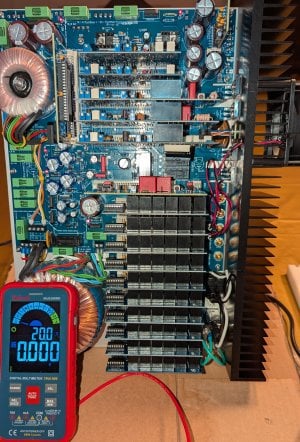

As I suspect at least some other people also have, I've amassed a collection of tubes over the decades. I'm making a committed effort to sort out a life of vacuum tubeage. This requires that I go through all the vacuum tubes I've got. To aide in this, given the sizeable scope, I built a RoeTest V11 vacuum tube testing system. It looked like a better tool to manage the production level required, rather than my vintage testers (mostly a TV-7D/U and Heathkit TT-1).

I've bumped into some curiosities, mostly with the 6080s and 6AS7Gs I've acquired in support of my much loved Crack. My typical protocol when acquiring any tube is to test it with at least one tester, often two. If it doesn't show any terminal defects, after testing, I then give it a check in-circuit. And I do this as soon as possible after purchase to bring up any issues with the seller. There are some rare exceptions when I do only part of that, and rarer, none of that.

I went to sort through 20 NIB French Thomson 6080WAs, and also to enjoy rolling one or two of these into my Crack. Most I had previously double-tested (they had test results written on them in Sharpie pen), with some also checked in-circuit.

I checked each one with the RoeTest. All tested well, and test results corroborated closely enough with tests done previously with the vintage testers.

BUT, I then tried one in the Crack. Nothing. No output. Took it out, tested it. Heaters heated, but little to no output. I went through all of them. Of the 20, there are 10 good ones, a couple useable/marginal ones, and the rest are dead. ??!! Crack tests just fine. I went through resistance and voltage checks, and all's well there. The other 6080s and 6AS7Gs I have out and on-hand to use in the Crack all tested and worked just fine.

This leaves the issue apparently and squarely with Thomson 6080s. PB being his helpful, responsive self reported to a post I made about this that he knew of some issues with eBay-sourced Thomson 6080s.

I had never seen a situation like this before where so many of the same brand, apparently NIB tubes show the same kind of terminal problem. I had some Tung Sol 6550s that had a tendency to show grid current draw more often than any other 6550 or KT88 I used. So, some tube brands, vintages, construction types might show some different, notable behavior tendencies, and I have heard some tube sellers, people who see far more tubes than I do, report some behaviors that show up from certain manufacturers, tube batches, etc., but I hadn't seen this happen in my own tube population.

Chasing this further, I posted my experience to another group. Got some interesting replies. A report that vacuum tubes have internal fusing and that all vintage tubes (kinda most specifically referring to NOS) need conditioning before use, like up to a week of continuously running only the heater before any other voltages are applied.

I know something about tube production process, activation, conditioning, and related downstream to this, rejuvenating or cooking. I've heard of ways cathodes can be damaged; stripping, poisoning, contamination/oxidation, mechanical issues. There are lots of ways a tube can fail/stop working, on rare occasion this can be quite dramatic with sparks, bright orange plates, nasty noises, and more. It can be due to issues with the gear, but in the cases I've had problems it's been due to a tube defect.

I've not though seen, read, heard anywhere in my tubed audio journey that a careful post-production conditioning, or re-conditioning, is essentially necessary. Nor, that tubes have internal fuses. Some tubes have connection wiring that provides a flash of start up resistance. Sometimes some of these wiring connections can come unconnected. The Conrad-Johnson amplifiers I had had plate fuses. Tubes will change their performance over time. Sometimes tube performance improves or stabilizes with some use. Sometimes it gets worse. Ultimately, they all fade away.

The RoeTest allows you to set and measure any tube test parameter independently, and has a feature to create automated rejuvenation programs. I get how this works, but haven't worked through this in detail. Some of those near-death Thomsons might be candidates to experiment with this.

Rejuvenation? Cooking? Internal built in fuses?

Thoughts?

Thanks.

As I suspect at least some other people also have, I've amassed a collection of tubes over the decades. I'm making a committed effort to sort out a life of vacuum tubeage. This requires that I go through all the vacuum tubes I've got. To aide in this, given the sizeable scope, I built a RoeTest V11 vacuum tube testing system. It looked like a better tool to manage the production level required, rather than my vintage testers (mostly a TV-7D/U and Heathkit TT-1).

I've bumped into some curiosities, mostly with the 6080s and 6AS7Gs I've acquired in support of my much loved Crack. My typical protocol when acquiring any tube is to test it with at least one tester, often two. If it doesn't show any terminal defects, after testing, I then give it a check in-circuit. And I do this as soon as possible after purchase to bring up any issues with the seller. There are some rare exceptions when I do only part of that, and rarer, none of that.

I went to sort through 20 NIB French Thomson 6080WAs, and also to enjoy rolling one or two of these into my Crack. Most I had previously double-tested (they had test results written on them in Sharpie pen), with some also checked in-circuit.

I checked each one with the RoeTest. All tested well, and test results corroborated closely enough with tests done previously with the vintage testers.

BUT, I then tried one in the Crack. Nothing. No output. Took it out, tested it. Heaters heated, but little to no output. I went through all of them. Of the 20, there are 10 good ones, a couple useable/marginal ones, and the rest are dead. ??!! Crack tests just fine. I went through resistance and voltage checks, and all's well there. The other 6080s and 6AS7Gs I have out and on-hand to use in the Crack all tested and worked just fine.

This leaves the issue apparently and squarely with Thomson 6080s. PB being his helpful, responsive self reported to a post I made about this that he knew of some issues with eBay-sourced Thomson 6080s.

I had never seen a situation like this before where so many of the same brand, apparently NIB tubes show the same kind of terminal problem. I had some Tung Sol 6550s that had a tendency to show grid current draw more often than any other 6550 or KT88 I used. So, some tube brands, vintages, construction types might show some different, notable behavior tendencies, and I have heard some tube sellers, people who see far more tubes than I do, report some behaviors that show up from certain manufacturers, tube batches, etc., but I hadn't seen this happen in my own tube population.

Chasing this further, I posted my experience to another group. Got some interesting replies. A report that vacuum tubes have internal fusing and that all vintage tubes (kinda most specifically referring to NOS) need conditioning before use, like up to a week of continuously running only the heater before any other voltages are applied.

I know something about tube production process, activation, conditioning, and related downstream to this, rejuvenating or cooking. I've heard of ways cathodes can be damaged; stripping, poisoning, contamination/oxidation, mechanical issues. There are lots of ways a tube can fail/stop working, on rare occasion this can be quite dramatic with sparks, bright orange plates, nasty noises, and more. It can be due to issues with the gear, but in the cases I've had problems it's been due to a tube defect.

I've not though seen, read, heard anywhere in my tubed audio journey that a careful post-production conditioning, or re-conditioning, is essentially necessary. Nor, that tubes have internal fuses. Some tubes have connection wiring that provides a flash of start up resistance. Sometimes some of these wiring connections can come unconnected. The Conrad-Johnson amplifiers I had had plate fuses. Tubes will change their performance over time. Sometimes tube performance improves or stabilizes with some use. Sometimes it gets worse. Ultimately, they all fade away.

The RoeTest allows you to set and measure any tube test parameter independently, and has a feature to create automated rejuvenation programs. I get how this works, but haven't worked through this in detail. Some of those near-death Thomsons might be candidates to experiment with this.

Rejuvenation? Cooking? Internal built in fuses?

Thoughts?

Thanks.

Last edited: