Hi There,

After my Crack and Speed Ball has been working for 2 weeks, it has decided to exhibit some problems.

The left channel dies out after about 5 minutes of usage (you can hear it very barely). Before it dies, the left channel will have some loud static, then it pops and dies.

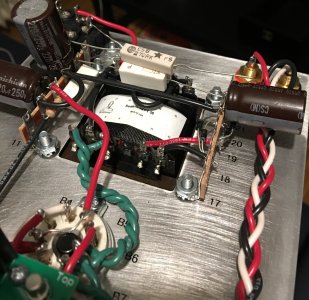

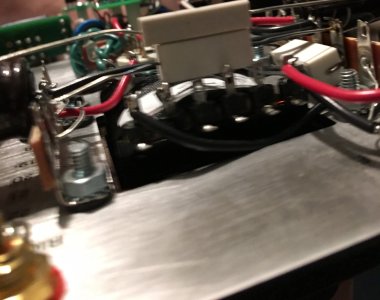

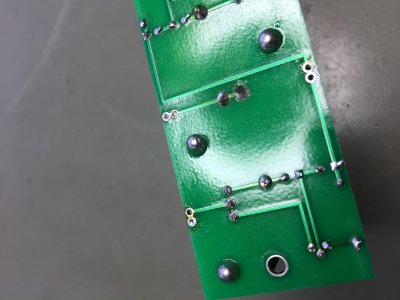

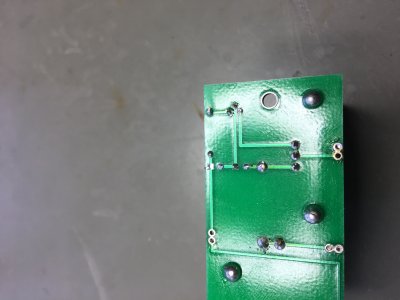

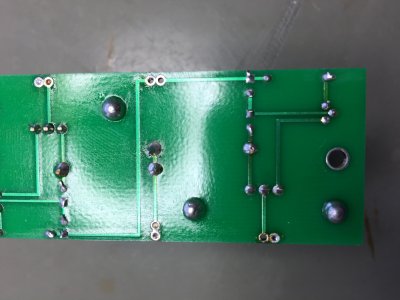

I resoldered all the joints on the tube sockets and the the OA transistor on the bigboard.

I tapped on all the solder joints, and no popping sounds come from it, so I think the solder joints on the terminals and sockets are good.

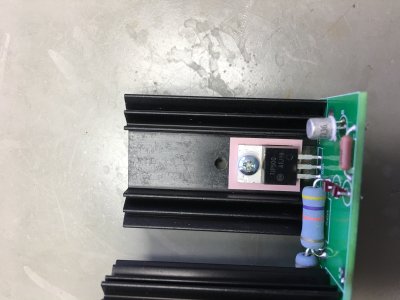

When the left channel dies out, the LED closest to the transistor at OA on the big board stops glowing.

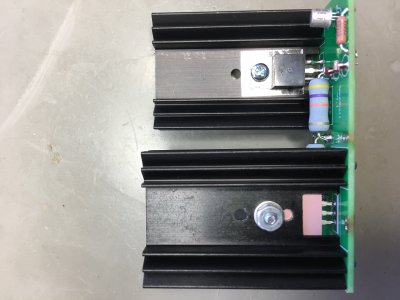

I also measured the temperatures at some points.

The white ceramic resistors by the transformers are anywhere between 120-150 degrees Celsius when the left channel dies.

The transistor at OA on the bigboard is between 63-79 degrees., while the transistor at OB is at 47 degrees.

Once i let it cool off, and turn it on again, it works again for 5 minutes before the left channel fails again.

In those 5 minutes the voltages are correct.

One thing I noticed is when the left channel dies, the temperature sky rises on the mentioned resistors and transistor.

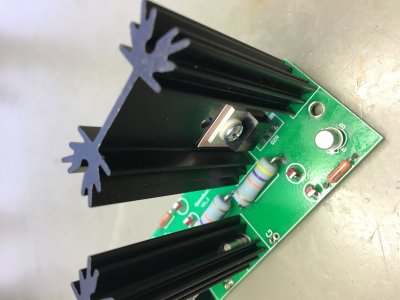

I took off the isolation sheet on the transistor and made sure that I put the vinyl tab on correctly, along with putting the isolation sheet back on.

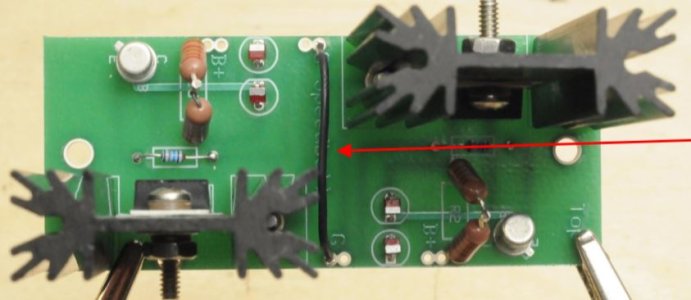

Here are the voltages for the little board, big board and terminals.

Voltages not in range are listed in red.

Any help or advice is appreciated, thank you!

After my Crack and Speed Ball has been working for 2 weeks, it has decided to exhibit some problems.

The left channel dies out after about 5 minutes of usage (you can hear it very barely). Before it dies, the left channel will have some loud static, then it pops and dies.

I resoldered all the joints on the tube sockets and the the OA transistor on the bigboard.

I tapped on all the solder joints, and no popping sounds come from it, so I think the solder joints on the terminals and sockets are good.

When the left channel dies out, the LED closest to the transistor at OA on the big board stops glowing.

I also measured the temperatures at some points.

The white ceramic resistors by the transformers are anywhere between 120-150 degrees Celsius when the left channel dies.

The transistor at OA on the bigboard is between 63-79 degrees., while the transistor at OB is at 47 degrees.

Once i let it cool off, and turn it on again, it works again for 5 minutes before the left channel fails again.

In those 5 minutes the voltages are correct.

One thing I noticed is when the left channel dies, the temperature sky rises on the mentioned resistors and transistor.

I took off the isolation sheet on the transistor and made sure that I put the vinyl tab on correctly, along with putting the isolation sheet back on.

Here are the voltages for the little board, big board and terminals.

Voltages not in range are listed in red.

Any help or advice is appreciated, thank you!

| Terminals | Big Board | Litte Board |

| 1: 75.4V | OA: 55V | OA: 75.4V |

| 2: 90.6V | OB: 76.6V | IA: 90.8 |

| 3: 0V | G: 0V | B-A/B: 0V |

| 4: 90.6V | B+: 92.5V | IB: 90.8V |

| 5: 54.8V | OB: 55V | |

| 6: 0V |

| 7: 76.3V |

| 8: 0V |

| 9: 53.5V |

| 10: 0V |