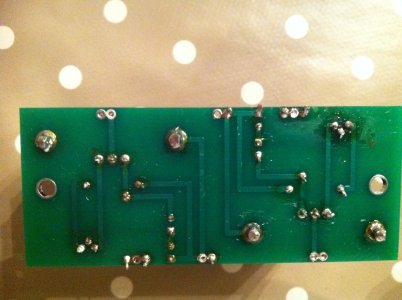

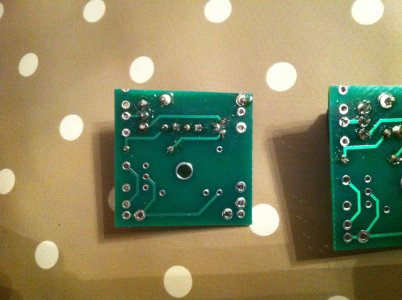

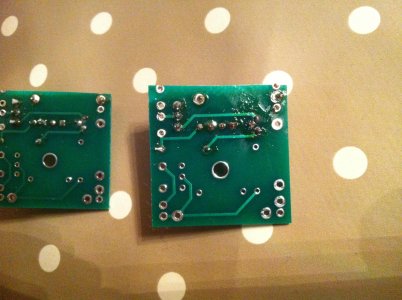

I would say that there is a little too much solder on the underside of that PC board. Some of it may have wicked up under those 2N2222A's and shorted the case to other legs.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Problems after speedball(Solved)

- Thread starter Strikkflypilot

- Start date

Strikkflypilot

New member

So I ve tried again.

Enjoyed the stock crack immensely for two days or so.

Now I have resoldered ALL the speedball legs and ALL the

terminals.

Like last time, the two leds on the bigboard close to the PS

wont light up.

Before I soldered the PCBs I checked all the conducting and AGAIN,

only the one diode closest to the TIP50 on the side that doesnt

Light up measures weird.

I couldnt find a voltage drop or measurable resistanc over

it, no matter the polarity of the testing

I would already have ordered a replacement but cant find a replacement

6000.

Do You think something else is wrong?

1. Drop from 65v

2. Drop from 100v

3. 16mV

4. Drop from 100v

5. 75,92v

6. 16mV

7. Drop from 65v

8. 16mv

9. 77,6V

10. 16mV

11. 16mv

12. 0v

13. Drop from 100v

14. 0v

15. 144v

20. 0v

21. 193,1v.

Am I missing something?

Enjoyed the stock crack immensely for two days or so.

Now I have resoldered ALL the speedball legs and ALL the

terminals.

Like last time, the two leds on the bigboard close to the PS

wont light up.

Before I soldered the PCBs I checked all the conducting and AGAIN,

only the one diode closest to the TIP50 on the side that doesnt

Light up measures weird.

I couldnt find a voltage drop or measurable resistanc over

it, no matter the polarity of the testing

I would already have ordered a replacement but cant find a replacement

6000.

Do You think something else is wrong?

1. Drop from 65v

2. Drop from 100v

3. 16mV

4. Drop from 100v

5. 75,92v

6. 16mV

7. Drop from 65v

8. 16mv

9. 77,6V

10. 16mV

11. 16mv

12. 0v

13. Drop from 100v

14. 0v

15. 144v

20. 0v

21. 193,1v.

Am I missing something?

Attachments

Can you try rotating the big pc board 180 degrees and installing it that way.

If so, does the same side stay dark?

If the dark side also rotates with the board, then I would replace both the transistors on that side, using as little solder on the 2N2222A's as is possible.

If the dark side remains to the rear of the amp, then there is a wiring issue with the installation that we can troubleshoot at that time.

If so, does the same side stay dark?

If the dark side also rotates with the board, then I would replace both the transistors on that side, using as little solder on the 2N2222A's as is possible.

If the dark side remains to the rear of the amp, then there is a wiring issue with the installation that we can troubleshoot at that time.

Strikkflypilot

New member

Well done.

Yes, that is fried transistor(s).

-PB

Yes, that is fried transistor(s).

-PB

Strikkflypilot

New member

I thank You Sir.

I did have a spark from the middle leg of That

particular TIP50 during conduction test. At that point the

2N2s had bad solders.

My theory is that the one LED I keep writing about bought it

since, well, Ive gone on and on about it enough.

So I replace the TIP50, 2N2222A and, indulge me , the dead LED

, the dead LED

on the dark half of the bigboard, yes?

Would You be so kind to mail me their datasheets so I order the right ones?

Yours truly

Strikkflypilot

I did have a spark from the middle leg of That

particular TIP50 during conduction test. At that point the

2N2s had bad solders.

My theory is that the one LED I keep writing about bought it

since, well, Ive gone on and on about it enough.

So I replace the TIP50, 2N2222A and, indulge me

on the dark half of the bigboard, yes?

Would You be so kind to mail me their datasheets so I order the right ones?

Yours truly

Strikkflypilot

A blown LED will literally explode. Yours is OK.

Any old tip50 will work. The 2N2222A should be in a metal can, but otherwise the variations aren't super important.

PB

Any old tip50 will work. The 2N2222A should be in a metal can, but otherwise the variations aren't super important.

PB

Strikkflypilot

New member

I have ordered two of a kind from different manufacturers.

Would You have changed transistors on both sides or just the one

currently without current? Just so they are as similar as possible?

Lots of people go on about how material changes makes all the difference

in sound quality.

Would You have changed transistors on both sides or just the one

currently without current? Just so they are as similar as possible?

Lots of people go on about how material changes makes all the difference

in sound quality.

I would focus on getting the dark side to work first.

-PB

-PB

Strikkflypilot

New member

Thanks.

Will do as soon as they are delivered.

Will do as soon as they are delivered.

Strikkflypilot

New member

Thanks for all help thus far, CB.

I Removed all transistor/LEDs on the dark half

LEDs had no voltage drop, even out of curcuit

The 2N2222A was kinda dark/ blueishblack and burned looking

The TIP50 looked good but I changed it all the same.

After reconnecting, all LEDs lighted up and Voltages are good.

Just haven't had time to listen in yet. Very excited

I Removed all transistor/LEDs on the dark half

LEDs had no voltage drop, even out of curcuit

The 2N2222A was kinda dark/ blueishblack and burned looking

The TIP50 looked good but I changed it all the same.

After reconnecting, all LEDs lighted up and Voltages are good.

Just haven't had time to listen in yet. Very excited

Strikkflypilot

New member

Ok.

Was excited to try some music

I switch the crack + SB on.

After about 6 seconds the 6080 lights up blueish before it lights as usual(wires in reddish light) after about 10 seconds, when a humming starts (about 80-85 Hz like a ground loop?)that is first noticabe on the left, then also on the right channel although slightly weaker. This humming gets considerably louder up to 20 seconds. On a cold amp it wears out at about 60 seconds. Faster on hot amp, maybe 15 seconds after it gets loud.

From then on it is quiet until I turn the volume all the way down which makes the noise on both channels with max noise. When I turn the volume all the way up to 100% it is also noise with left>right. In between it is quiet

If I attach a source, there is only a slight hum which gets louder from about 70% volume to 100%. Ig I turn volume all the way down, the noise is back to max binaurally.

In between, as in 0%<,>100% the Sound quality seems sweet, but it is overshadowed by the other issues...

Again I ask for help. And of course, here are the voltages witj SB installed:

1. 73,4 v

2. 173,45 v

3. 0 v

4. 173,41 v

5. 76,8 v

6. 0 v

7. 101,86

8. 0 v

9. 102,8 v

10. 0 v

11. 0 v

12. 0 v

13. 173,1 v

14. 0 v

15. 192,33 v

16. 0v

17. 0 v

18. 87 v

19. 82,7 v

20. 0 v

21. 211,4 v

Hope this can be resolved.

Yours truly

Was excited to try some music

I switch the crack + SB on.

After about 6 seconds the 6080 lights up blueish before it lights as usual(wires in reddish light) after about 10 seconds, when a humming starts (about 80-85 Hz like a ground loop?)that is first noticabe on the left, then also on the right channel although slightly weaker. This humming gets considerably louder up to 20 seconds. On a cold amp it wears out at about 60 seconds. Faster on hot amp, maybe 15 seconds after it gets loud.

From then on it is quiet until I turn the volume all the way down which makes the noise on both channels with max noise. When I turn the volume all the way up to 100% it is also noise with left>right. In between it is quiet

If I attach a source, there is only a slight hum which gets louder from about 70% volume to 100%. Ig I turn volume all the way down, the noise is back to max binaurally.

In between, as in 0%<,>100% the Sound quality seems sweet, but it is overshadowed by the other issues...

Again I ask for help. And of course, here are the voltages witj SB installed:

1. 73,4 v

2. 173,45 v

3. 0 v

4. 173,41 v

5. 76,8 v

6. 0 v

7. 101,86

8. 0 v

9. 102,8 v

10. 0 v

11. 0 v

12. 0 v

13. 173,1 v

14. 0 v

15. 192,33 v

16. 0v

17. 0 v

18. 87 v

19. 82,7 v

20. 0 v

21. 211,4 v

Hope this can be resolved.

Yours truly

Strikkflypilot said:On a cold amp it wears out at about 60 seconds. Faster on hot amp, maybe 15 seconds after it gets loud.

This is noise that occurs during warmup, there isn't really anything to troubleshoot here.

Strikkflypilot

New member

Good to hear, really, but the constant noise at volume level 0 and the blue flash in the 6080 at 7 seconds is nothing to worry about or possible to mend? (ESpecially the volume 0 buzz is rather annoying and wasnt there before the SB)

The warmup characteristics of the amplifier change when installing the Speedball.

If you can't live with a bit of warmup time, you can reinstall the 22K resistors.

If you can't live with a bit of warmup time, you can reinstall the 22K resistors.

Strikkflypilot

New member

Thanks again for the reply. Appreciate Your diligence with this matter.

I can certainly live with the warmup time, just wasnt expecting it.

Is there a way to eliminate the loud buzz at 0 volume? It does NOT go away.

I can certainly live with the warmup time, just wasnt expecting it.

Is there a way to eliminate the loud buzz at 0 volume? It does NOT go away.

I am looking into replicating the issue with one of our Cracks and coming up with a solution.

Strikkflypilot

New member

Well, Caucasian Backplate.

After leaving it on a couple more minutes, also the 0 Volume buzz disappeard, like You said.

Shame on me :-[

I thank You very much for ALL Your help.

My amp is now working as designed.

Long Norwegian summernights with the classics ahead

After leaving it on a couple more minutes, also the 0 Volume buzz disappeard, like You said.

Shame on me :-[

I thank You very much for ALL Your help.

My amp is now working as designed.

Long Norwegian summernights with the classics ahead

Hi Strikkflypilot,

I have the exact same behaviour with my Crack+Speedball built a couple of weeks ago. Stock crack was completely silent, then with the speedball fitted I get mains hum at the start, getting louder then receding, and a low-volume buzz that goes away after a couple of minutes. I did all the suggested checks and am satisfied that the build is OK. I am more than happy with the sound. It did scare me the first time I heard the hum as I feared it would get ever-louder and break my HD650s (not to mention my ears) but happily not.

Cheers

Paul.

I have the exact same behaviour with my Crack+Speedball built a couple of weeks ago. Stock crack was completely silent, then with the speedball fitted I get mains hum at the start, getting louder then receding, and a low-volume buzz that goes away after a couple of minutes. I did all the suggested checks and am satisfied that the build is OK. I am more than happy with the sound. It did scare me the first time I heard the hum as I feared it would get ever-louder and break my HD650s (not to mention my ears) but happily not.

Cheers

Paul.

Strikkflypilot

New member

Thanks, pduk.

Nice to get that kind of feedback from a fellow builder.

Caucasian sure has walked me through this very thoroughly.

I hope the questions asked and answered will help those that also eventually will have questions of their own when building.

I could not be happier with the support here.

My most important tip for upcoming builders is this:

Check all solder joints! Not only by looking but with Your Multimeters.

Nice to get that kind of feedback from a fellow builder.

Caucasian sure has walked me through this very thoroughly.

I hope the questions asked and answered will help those that also eventually will have questions of their own when building.

I could not be happier with the support here.

My most important tip for upcoming builders is this:

Check all solder joints! Not only by looking but with Your Multimeters.

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 22

- Views

- 5K

- Replies

- 10

- Views

- 3K