Agweeks

New member

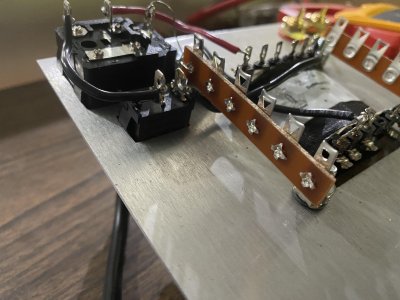

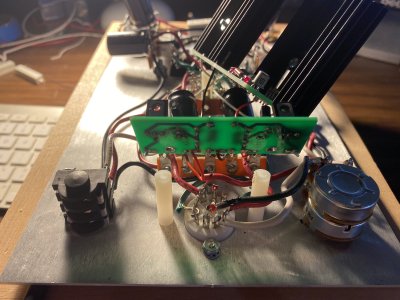

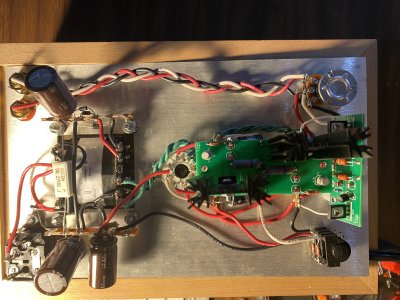

I have learned so much about amp building with my amp "build". I purchased a crack kit for this purpose. All the Youtube videos on soldering in the world just can't replace real-world experience. The initial build was/is so poor that it was/is riddled with problems. It has become a game of whoppamole. One problem solved creates another. I chase down one problem, reflow/resolder every visibly poor or weak solder joint in the process, sometimes repeatedly, trying to eradicate all of the problem and create another problem in the process.

I now know that I wasn't making a good mechanical connections with the leads and wires prior to soldering.

I wasn't getting my iron hot enough.

I was using way too much solder.

I was not allowing the flux to cook off after having the solder flow. I removed to iron too quickly, creating cold joint.

I didn't know what a good joint looked like.

I didn't know that flux is why the solder flows across the surfaces of all the parts and that is why you heat one side of the joint and add solder to the other side. I've seen this happen over and over now.

All of that being said, I would like to disassemble the amp, clean all the terminals and rewire the whole thing, now that I know what I'm doing. I have a solder sucker, the copper ribbon for removing solder and new hook up wire. My thinking is that I will have a more stable, better looking amp. It might even sound better. Who knows.

Can anyone give me any suggestions on how best to clean the connections? Am I on the right track? Is this overkill?

I now know that I wasn't making a good mechanical connections with the leads and wires prior to soldering.

I wasn't getting my iron hot enough.

I was using way too much solder.

I was not allowing the flux to cook off after having the solder flow. I removed to iron too quickly, creating cold joint.

I didn't know what a good joint looked like.

I didn't know that flux is why the solder flows across the surfaces of all the parts and that is why you heat one side of the joint and add solder to the other side. I've seen this happen over and over now.

All of that being said, I would like to disassemble the amp, clean all the terminals and rewire the whole thing, now that I know what I'm doing. I have a solder sucker, the copper ribbon for removing solder and new hook up wire. My thinking is that I will have a more stable, better looking amp. It might even sound better. Who knows.

Can anyone give me any suggestions on how best to clean the connections? Am I on the right track? Is this overkill?