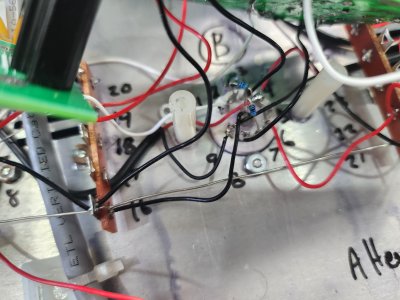

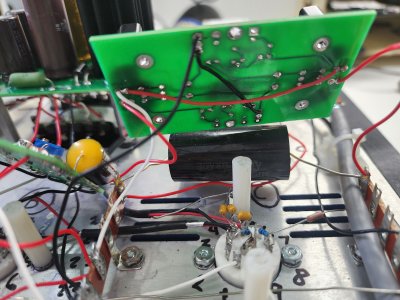

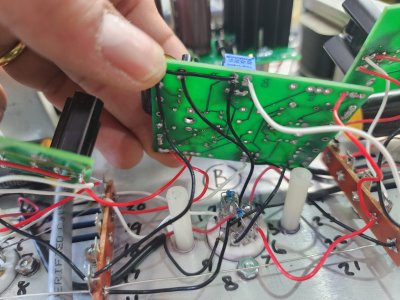

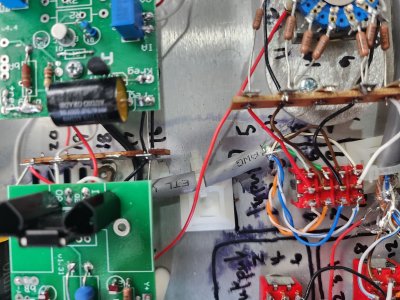

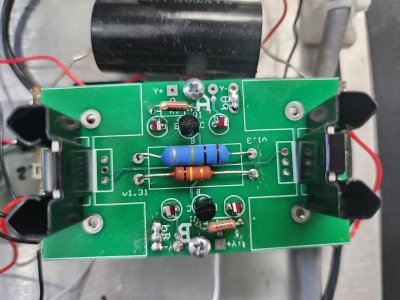

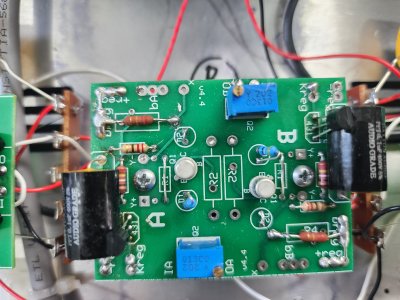

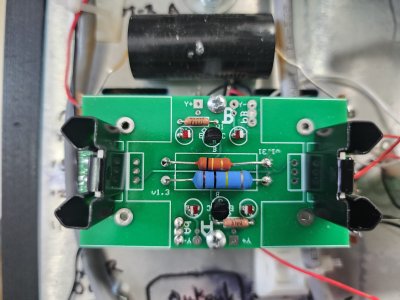

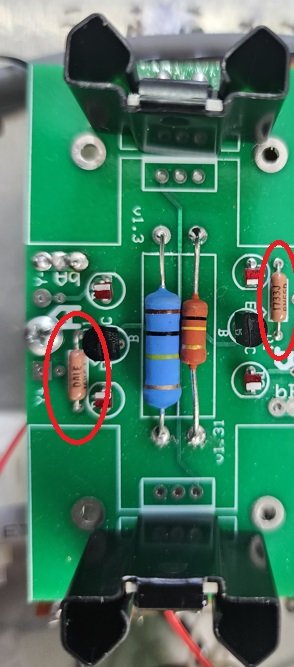

As best as I can tell, neither one of your 6C45P tubes is really drawing any current. This can happen if they aren't receiving heater voltages (if they aren't lighting up), from poor solder joints (especially the center leg of the MJE5731A on the B side of the C4S board in this case), or possibly having the R1 resistors on the high current C4S boards swapped.

The lower than expected Kreg voltages that you have tell us that the 12AU7 is tacking up the slack for the lack of current drawn by the 6C45P tubes, so it's unlikely that you have to be concerned with the A side of each high current C4S board, and likewise the outer portions of the center C4S board that hold the high voltage regulators seem to be operating happily.

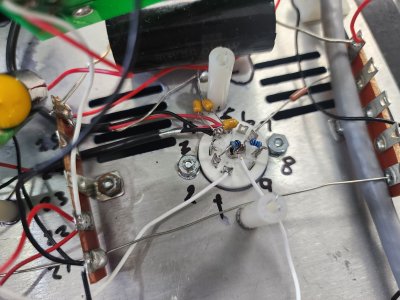

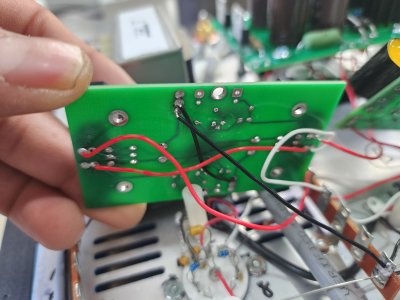

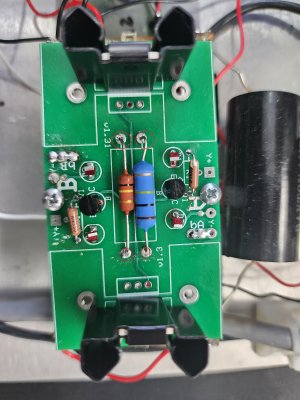

It is incredibly common for builders to make mistakes on that center PC board, especially forgetting to fold over the trim pot leads to make it into a variable resistor, but I don't see any obvious errors on yours.