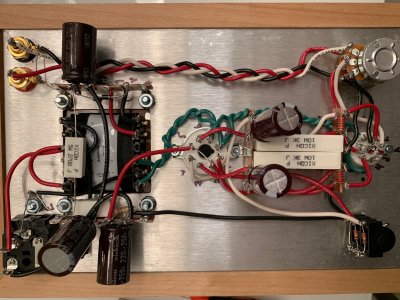

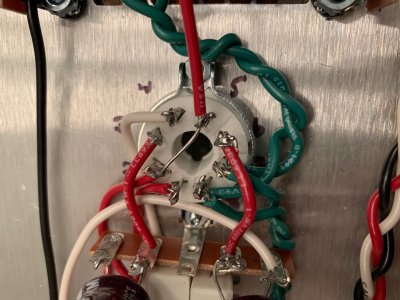

All done - very excited. All tests “seemed†right and within range, but once hooked up (and when music plays all seems well and better than that even) but noticed that of the 6080 is touched even slightly/lightly I get a loud static-like POP through the headphones.

Something loose? Something touching that shouldn’t be? It seems all good as long as nothing touches it, but that doesn’t seem so 100% as it should.

All advice and pathways appreciated.

Josh

Something loose? Something touching that shouldn’t be? It seems all good as long as nothing touches it, but that doesn’t seem so 100% as it should.

All advice and pathways appreciated.

Josh