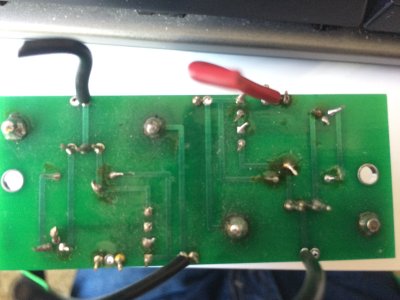

I messed up my install of the speedball, I have some waxy resin substance that is covering the connections of the board making a bridge (not sure if its conductive it came out of the soldier). I also am not sure if I installed the LED's right since I didn't install them upside down. Also I need more wire for the install. It was difficult before because my soldering iron was bad, now I have a good one.

What do you guys suggest I do?

What do you guys suggest I do?