The nuts are there to secure the transformer. Loose transformers vibrate, creating noise, and the grounding of the transformer is based on having a strong physical connection. If you ever ship your amplifier, you run the risk of having the transformer break free, quite possibly completely trashing your amp. Every part included in the kit is there for a reason, every step in the manual is there for a reason. It could be a matter of safety, or audio performance, or just to make a functional circuit.

You asked about the LEDs. They are there to bias the tube so it functions, they are not indicator lights. It is unclear from your pictures if they are oriented correctly or not. The stripe MUST be connected to the center pin of the socket. Also when I looked that picture to check, I noticed that the potentiometer is miswired. Did you already clear that up?

Your resistance checks are looking much better now. As for term 13, your meter will try to charge the capacitor, but it will also see the 270KΩ resistor. What a meter will show under these connections will vary from type to type. It will not be able to read the resistor when you have it set in a lower range. You would not be able to read that resistor with one probe on each lead on any setting other than 2000KΩ.

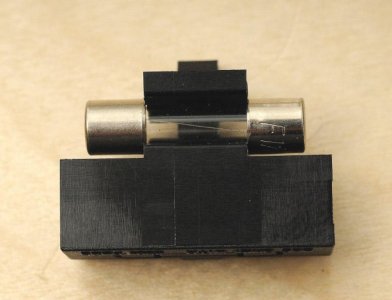

You can check your fuse to see if it is blown by setting your meter to the lowest resistance range and putting one probe on each end. You should read less than 1Ω if the fuse is good. Also a common mistake is to put the fuse in the portion of the holder meant to keep a spare fuse, rather than the part that actually puts it into use. See the pic attached.

I am unclear on what your last question means. Page 36 shows the completed Crack.