NightFlight

New member

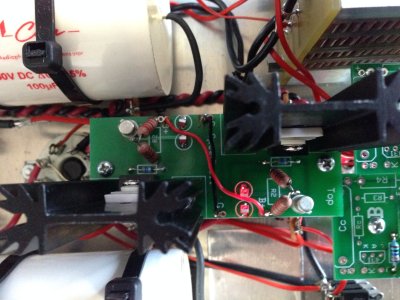

In belief that I have a possible heat issue, I installed ceramic isolators with heatsink compound on the TIP50 transistors... I must have broke the connection somehow on my right channel. The LED's closest to the B+ label there are not lighting up. I've re-flowed the 3 pins on the affected TIP50 to no avail.

Running with just the 6080 only the left channel LEDs light up and Left channel TIP50 produces heat. I see the ~200V on the middle pin of both the right and left channel TIP50's. But I what I don't see on the right side is the lower voltage of ~3V on the other two pins, as seen on the left channel.

Any pointers for isolation?

Running with just the 6080 only the left channel LEDs light up and Left channel TIP50 produces heat. I see the ~200V on the middle pin of both the right and left channel TIP50's. But I what I don't see on the right side is the lower voltage of ~3V on the other two pins, as seen on the left channel.

Any pointers for isolation?