My Beepre lives

and hums again!

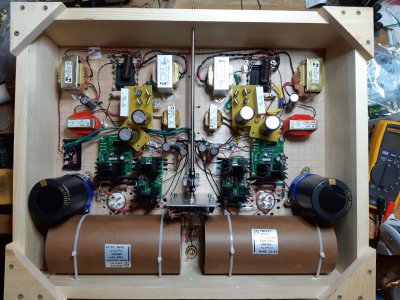

The hum is quieter but still there. But the real kicker is the wood frame adds 1 and 1/2 inches of extra width and length over the metal chassis that I spec'ed to fit my rack. So [the prototype] doesn't fit, and I can't listen to it in my main system. That is very disappointing. Not sure how i am going to solve this one. [Even without hum, I am at least a month away from doing the final build in the slightly smaller metal chassis] The Beepre has been out of commission since August, and I've not enjoyed listening without it. So I'm jonesing to listen to music through it again - even with a bit of hum.

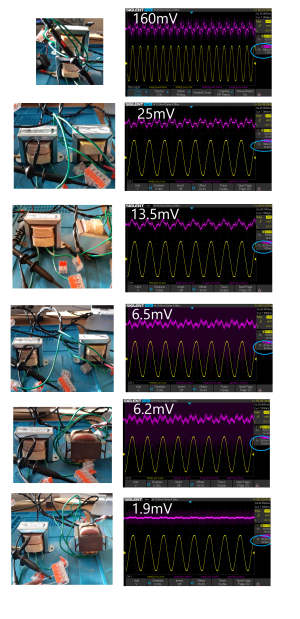

Re hum troubleshooting -- The B+ is about 20V high, so I will fix that today. I have no idea whether that could contribute to hum (e.g., by overworking the EL84 shunt reg), but it needs to be fixed in any event. I haven't yet mounted the transformers/chokes on L-brackets to get their cores perpendicular, so I can try that too. And if that doesn't do it, there's still a couple of grounding paths that I can play around with.

My best guess is that the hum is coupled onto the plate voltage supply. The signal wiring is well away from the magnetics, so I don't think that's were the hum is getting in.

On the upside: mounting the BeeQuiet internally on a L-bracket worked well, and I'm now so familiar with the BP circuit that I could probably draw the schematic with the right component values from memory (other than the solid state bits)!

Worst case scenario: I will rebuild it stock in the larger chassis that will accommodate the gigantic 10uF copper foil caps. But I'm still a long way off from giving up.

cheers, Derek

[bracketed edits added to clarify that the wood build is just a prototype, but I wanted to listen to it for the month or so it will take me to complete the metal work on the final build]]