D

Deke609

Guest

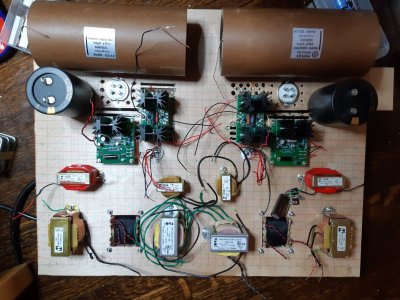

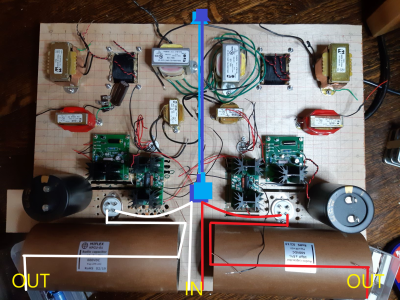

Here's my first stab at the layout of my BeePre rebuild. Does anyone see any howlers?

The gigantic caps are 10uF 600V copper foils that I originally intended to install in the Kaiju - but they were too big, even with the planned bigger chassis. The 600V is about 500V more than I need, but I can't find a 10uF 100-250V copper foil cap that isn't min $1K for a pair. These cost me half that on sale. So in they go!

cheers and thanks, Derek

The gigantic caps are 10uF 600V copper foils that I originally intended to install in the Kaiju - but they were too big, even with the planned bigger chassis. The 600V is about 500V more than I need, but I can't find a 10uF 100-250V copper foil cap that isn't min $1K for a pair. These cost me half that on sale. So in they go!

cheers and thanks, Derek