ALL212

New member

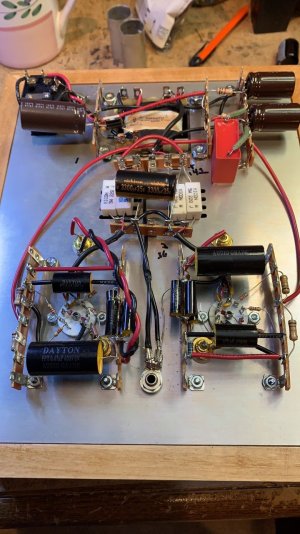

A friend of mine purchased a Reduction from the 'bay. Nice build, well done, however...

After some time horrible noises would come from one channel and in one case the speaker fuse blew.

I found a cold solder joint at 60 on the resistor. The wire had solder all around it but was not making a solid connection. If this resistor lost connection would it have done what he described as the symptoms?

I've reflowed the joint, ran all resistance checks and all voltage checks - everything checks fine.

Thanks!

After some time horrible noises would come from one channel and in one case the speaker fuse blew.

I found a cold solder joint at 60 on the resistor. The wire had solder all around it but was not making a solid connection. If this resistor lost connection would it have done what he described as the symptoms?

I've reflowed the joint, ran all resistance checks and all voltage checks - everything checks fine.

Thanks!