twofires

New member

Hi Bottleheads,

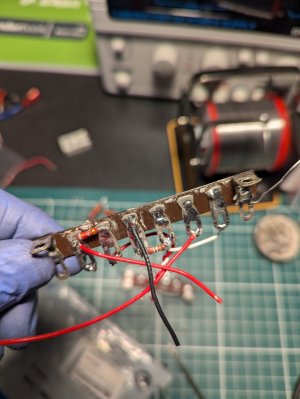

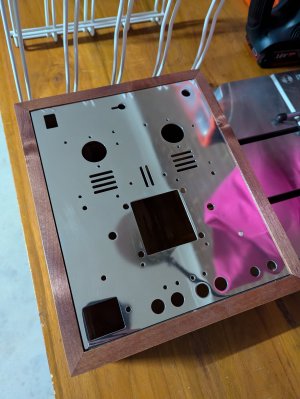

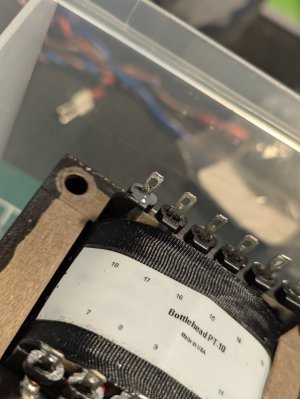

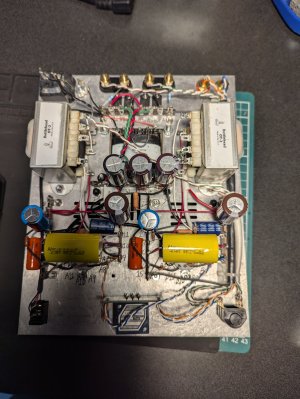

So, my SEX amp has an intermittent popping issue (through headphones and speakers) that is maybe once every hour of use, and is concerning enough that I'm just going to strip the whole thing down and start again. There was a water-soluble flux issue during the build, brought about by my inexperience, that may be causing intermittent shorts, and so I just want to clean the whole thing out, try again, and hope the transformers and chokes are okay.

Anyway, I'm able to account for pretty much every part, except for the shielded twisted pair power wiring w/drain wire. The closest I've found that isn't AUD$400 for a massive reel is this stuff:

https://catalog.belden.com/techdata/EN/8450_techdata.pdf

It's about AUD$95 for a 15m cut shipped from the US, but I can live with that.

The tech data says it's rated to 300V, but as there's around 400V flying around inside the amp, I thought I'd check if this is an appropriate substitute.

Also it seems 1.5uF 630V+ PP film caps are hard to find outside of this general purpose Vishay:

https://au.mouser.com/ProductDetail/Vishay-Roederstein/MKP1839515084HQ?qs=5W%252BGeepUzoc9cdLA%252BylF3g%3D%3D

and a rather chunky and expensive Mundorf M-Cap Supreme:

https://www.soundlabsgroup.com.au/p/Mundorf-MCAP-Supreme-1u5-600V-Capacitor.html

Is there any leeway with capacitance with that cap? What would raising it to 2uF do to the circuit?

Thanks in advance,

Simon

So, my SEX amp has an intermittent popping issue (through headphones and speakers) that is maybe once every hour of use, and is concerning enough that I'm just going to strip the whole thing down and start again. There was a water-soluble flux issue during the build, brought about by my inexperience, that may be causing intermittent shorts, and so I just want to clean the whole thing out, try again, and hope the transformers and chokes are okay.

Anyway, I'm able to account for pretty much every part, except for the shielded twisted pair power wiring w/drain wire. The closest I've found that isn't AUD$400 for a massive reel is this stuff:

https://catalog.belden.com/techdata/EN/8450_techdata.pdf

It's about AUD$95 for a 15m cut shipped from the US, but I can live with that.

The tech data says it's rated to 300V, but as there's around 400V flying around inside the amp, I thought I'd check if this is an appropriate substitute.

Also it seems 1.5uF 630V+ PP film caps are hard to find outside of this general purpose Vishay:

https://au.mouser.com/ProductDetail/Vishay-Roederstein/MKP1839515084HQ?qs=5W%252BGeepUzoc9cdLA%252BylF3g%3D%3D

and a rather chunky and expensive Mundorf M-Cap Supreme:

https://www.soundlabsgroup.com.au/p/Mundorf-MCAP-Supreme-1u5-600V-Capacitor.html

Is there any leeway with capacitance with that cap? What would raising it to 2uF do to the circuit?

Thanks in advance,

Simon