Hi all,

My crack has been functioning fine before the attempted upgrade.

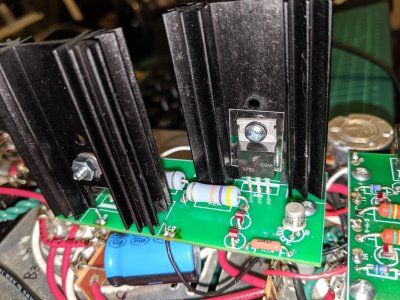

All resistance tests passed - Large PCB tests came back as over limit. LEDs on the small PCB and the tube connector below it are all good and glowing, but those on the large PCB aren't lighting up at all and my DC voltage measurements are all wrong too.

I'm in Australia, so mains power is approx. 220V

OB - 207V

G - 223

B+ - 95.5

OA - started near 178 and slowly ticked down to 150V

I'm pretty sure that there was no faulty soldering for the Large PCB.

Help?

My crack has been functioning fine before the attempted upgrade.

All resistance tests passed - Large PCB tests came back as over limit. LEDs on the small PCB and the tube connector below it are all good and glowing, but those on the large PCB aren't lighting up at all and my DC voltage measurements are all wrong too.

I'm in Australia, so mains power is approx. 220V

OB - 207V

G - 223

B+ - 95.5

OA - started near 178 and slowly ticked down to 150V

I'm pretty sure that there was no faulty soldering for the Large PCB.

Help?