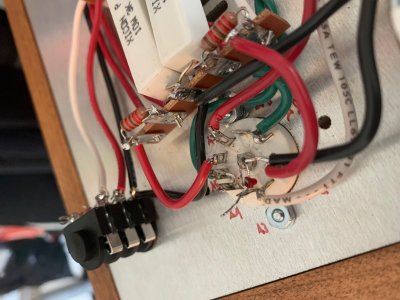

The initial build of my Crack got as far as the voltage test. The voltages were all within range except 1 and 7. The values were: 1) 155.4, 2) 170.3, 3) ~0, 4) 170.3, 5) 78.3, 6) ~0, 7) 155.1, 8) ~0, 9) 103.3, and 10) ~0. I'm not sure where the error is here, but I suspect 155.1 v for 7) is way too high. I'm thinking 155 for 1) is also too high. Any suggestions?

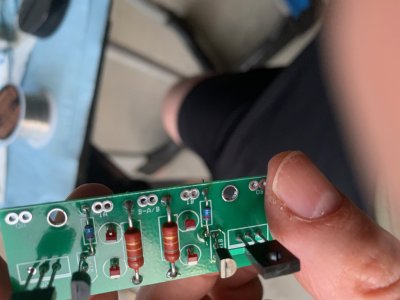

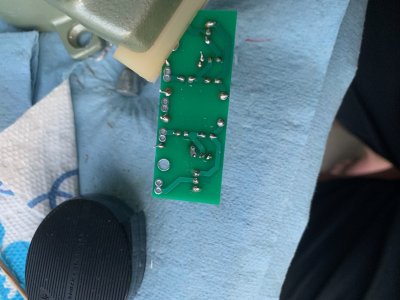

Also, I decided to resolder the LEDs since I couldn't tell if they were lit or not. (I build in the garage using daylight since that's all I've got.) I broke one of the leads for one of them during the reinstall. Is this the correct part for a reorder: Mouser 630-HLMP-6000 ?

Many thanks,

/d

Also, I decided to resolder the LEDs since I couldn't tell if they were lit or not. (I build in the garage using daylight since that's all I've got.) I broke one of the leads for one of them during the reinstall. Is this the correct part for a reorder: Mouser 630-HLMP-6000 ?

Many thanks,

/d