Thermioniclife

Member

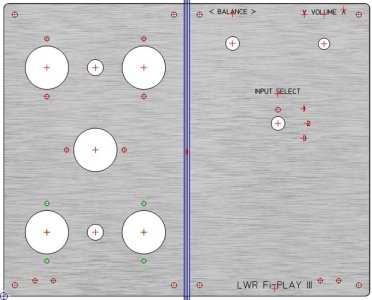

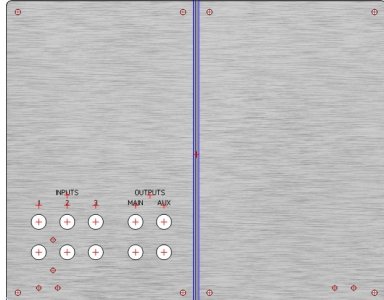

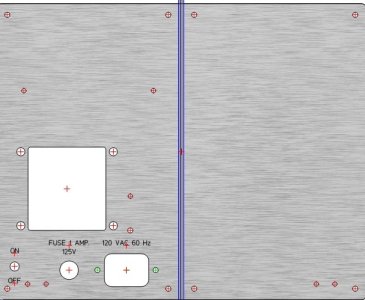

Ok here we go, a while ago i built a new version of the classic Bottlehead Foreplay III. I used 4x 7193 and 1 Od3/VR150.

I love it. During that build i wanted to build it in a Don Garber type chassis but i chickened out. Well i decided to go ahead and design a set of chassis plates to replicate the style of a Don Garber Y Preamp.

Here are some pic's of the panels i have ordered from FPE. I should have them in about 8-10 days. Being impatient as i am i pre built the HV and the Heater supply on wooden blocks, hopefully they will drop in. Each panel will be bent to a 120 degree angle.

Thanks Eileen for the power transformer, Luv ya.

Stay tuned for further developments.

Peace out, stay cool and safe.

,

I love it. During that build i wanted to build it in a Don Garber type chassis but i chickened out. Well i decided to go ahead and design a set of chassis plates to replicate the style of a Don Garber Y Preamp.

Here are some pic's of the panels i have ordered from FPE. I should have them in about 8-10 days. Being impatient as i am i pre built the HV and the Heater supply on wooden blocks, hopefully they will drop in. Each panel will be bent to a 120 degree angle.

Thanks Eileen for the power transformer, Luv ya.

Stay tuned for further developments.

Peace out, stay cool and safe.

,