My Crack+SB has been working fine over the past year with many tube rolling adventures.

However one evening I came across large popping sounds in both channels before leaving channel imbalance with weak to no sound on the Right channel.

Everytime I power it on now starts with popping sounds, followed with weak and gradually fading sound on the right.

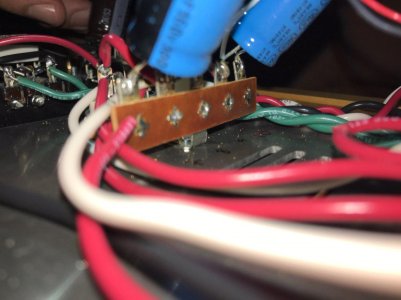

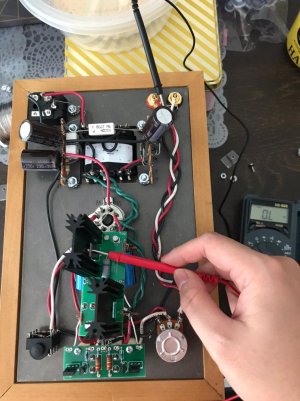

These are the current Voltage reading after doing a reheating of the solder links:

OA: 50.9V

OB: 80.5V

G: 1.9mV

B+: 97.3V

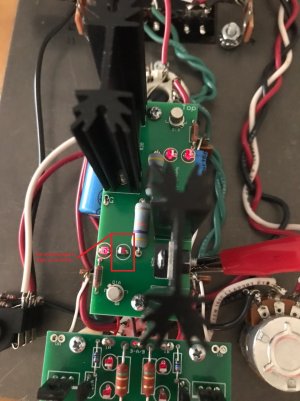

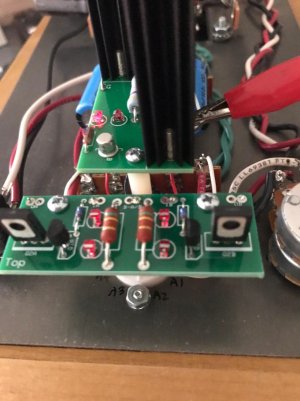

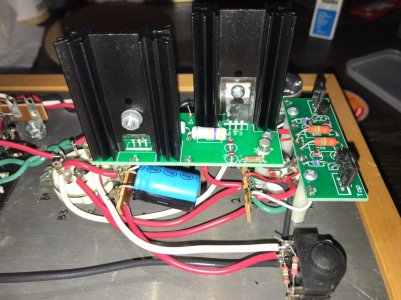

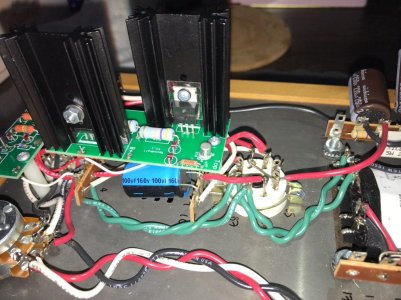

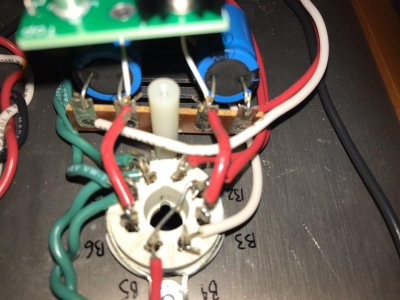

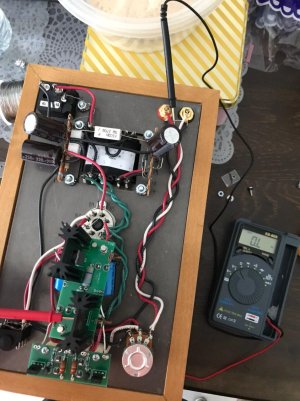

I'm attaching pictures showing the led lights, noticed that 01 at R2A doesn't shine as bright as the rest anymore..

The amp was working fine with no imbalance, capable of driving my 600ohm dt880 to deafening levels. So am definitely bummed out it can't work now, just that i'm not sure what is wrong/to check.

Any guidance is greatly appreciated .

.

However one evening I came across large popping sounds in both channels before leaving channel imbalance with weak to no sound on the Right channel.

Everytime I power it on now starts with popping sounds, followed with weak and gradually fading sound on the right.

These are the current Voltage reading after doing a reheating of the solder links:

OA: 50.9V

OB: 80.5V

G: 1.9mV

B+: 97.3V

I'm attaching pictures showing the led lights, noticed that 01 at R2A doesn't shine as bright as the rest anymore..

The amp was working fine with no imbalance, capable of driving my 600ohm dt880 to deafening levels. So am definitely bummed out it can't work now, just that i'm not sure what is wrong/to check.

Any guidance is greatly appreciated