AllanMarcus

New member

Hello,

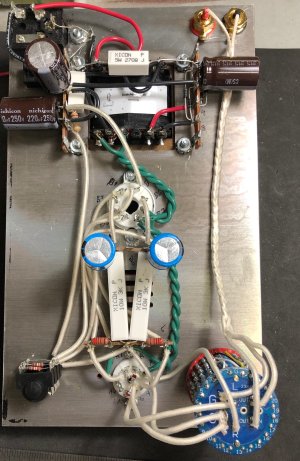

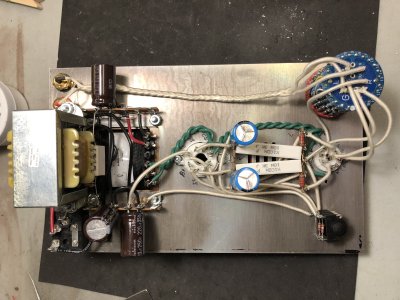

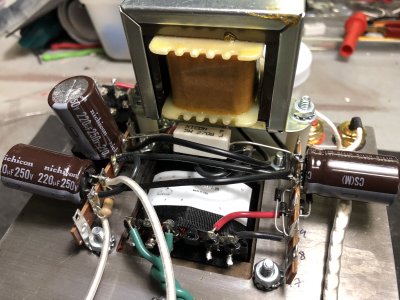

I recently finished my basic build of my second Crack. For this Crack I replaced all the signal path wire (I think) with 24AWG solid core, 99.99% silver wire (because I had some). The silver wire is sleeved in cotton, and mostly covered in clear heat shrink. I also upgraded the pot with a stepped attenuator.

I'm looking for comments on the signal path. I tried to follow some other threads on the same topic here, but none were definitive. Also, will I regret using 24AWG wire? It's what I had. I wasn't married to silver wire, but I had it, so what the heck.

I will add the speedball next, then a choke.

Thanks,

Allan

I recently finished my basic build of my second Crack. For this Crack I replaced all the signal path wire (I think) with 24AWG solid core, 99.99% silver wire (because I had some). The silver wire is sleeved in cotton, and mostly covered in clear heat shrink. I also upgraded the pot with a stepped attenuator.

I'm looking for comments on the signal path. I tried to follow some other threads on the same topic here, but none were definitive. Also, will I regret using 24AWG wire? It's what I had. I wasn't married to silver wire, but I had it, so what the heck.

I will add the speedball next, then a choke.

Thanks,

Allan