JeffYoung

New member

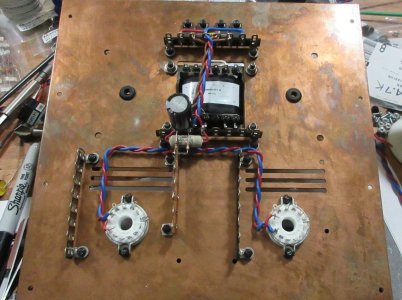

Being not generally a fan of the "top plate" style of amplifier, I'm constructing some custom casework for my S.E.X.

Top and bottom are 2mm copper plate, machined and then pickled in vinegar & salt and baked for 5 min at 450º. Since the connectors & controls are on the front and back, I've gone for a square plan (250mm x 250mm), which also gives me a bit more width to fit some bigger caps under the hood.

Sides are 1/2" x 2-1/2" aluminium bar; front and back are 0.090" aluminium plate. The front, back and sides are inset about 1/16" to give a bit of an "ice-cream sandwich" look. (In hindsight I think 1/8" or 3/16" inset would have looked better.)

The holes in the back might look a little odd: I've switched out the speaker posts for some vintage-style ones to go with the casework better. Same for the front: the power switch is rotary (with a chicken-head knob), while the volume pot is an Alps with a big Dakaware knob.

Front, back, sides, output chokes and transformer bell painted in wrinkle-finish paint.

Top and bottom are 2mm copper plate, machined and then pickled in vinegar & salt and baked for 5 min at 450º. Since the connectors & controls are on the front and back, I've gone for a square plan (250mm x 250mm), which also gives me a bit more width to fit some bigger caps under the hood.

Sides are 1/2" x 2-1/2" aluminium bar; front and back are 0.090" aluminium plate. The front, back and sides are inset about 1/16" to give a bit of an "ice-cream sandwich" look. (In hindsight I think 1/8" or 3/16" inset would have looked better.)

The holes in the back might look a little odd: I've switched out the speaker posts for some vintage-style ones to go with the casework better. Same for the front: the power switch is rotary (with a chicken-head knob), while the volume pot is an Alps with a big Dakaware knob.

Front, back, sides, output chokes and transformer bell painted in wrinkle-finish paint.