ccmccull

New member

I've been running this for a few months now and ... wow. It's a huge step up from my Mani. Spacious, dynamic, engaging. I never knew vinyl could sound so great.

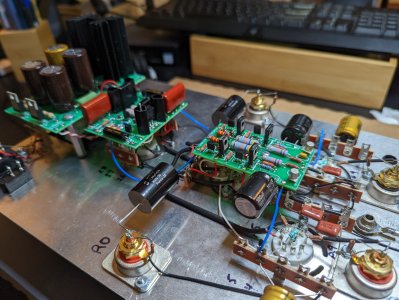

Here are a few vanity shots because I'm proud of myself!

I polished the transformer bell end with barkeeper's friend then sprayed it with clear lacquer. The barkeeper's friend gave me exactly the finish I wanted - a perfect even satin.

I coated the base with 3 coats of water-based polyurethane with 220 grit between coats. That stuff takes a lot of practice to get right and not bubble on you - on my 4th bh kit I think I finally have the technique down.

Here are a few vanity shots because I'm proud of myself!

I polished the transformer bell end with barkeeper's friend then sprayed it with clear lacquer. The barkeeper's friend gave me exactly the finish I wanted - a perfect even satin.

I coated the base with 3 coats of water-based polyurethane with 220 grit between coats. That stuff takes a lot of practice to get right and not bubble on you - on my 4th bh kit I think I finally have the technique down.