iamjanco

New member

Hi folks,

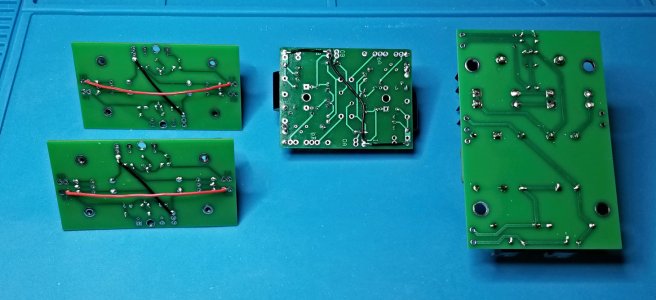

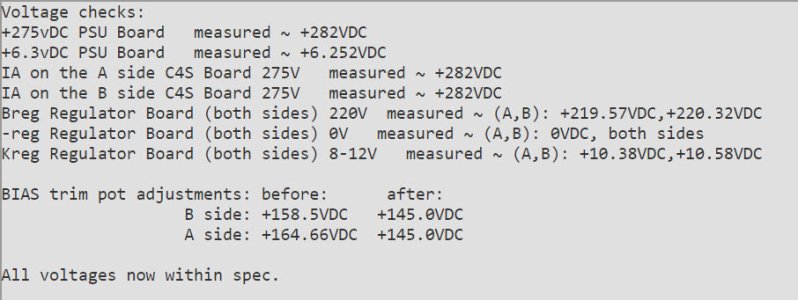

Back in June I mentioned that I picked up an unbuilt Mainline kit via ebay and I just managed to to start working on it the past few days. I decided not to go with a custom panel of my own design and used the panel that comes with the kit instead, polishing out its top surface to a semi-mirror gloss. I did opt for a custom frame as mentioned in my original thread, the results of which follow in the attachments below.

Anyway, I was able to assemble the hardware and circuit boards and now am getting ready to do the chassis wiring.

Figured I'd share the results thus far, just in case anyone's interested.

Cheers and Happy Holidays!

Back in June I mentioned that I picked up an unbuilt Mainline kit via ebay and I just managed to to start working on it the past few days. I decided not to go with a custom panel of my own design and used the panel that comes with the kit instead, polishing out its top surface to a semi-mirror gloss. I did opt for a custom frame as mentioned in my original thread, the results of which follow in the attachments below.

Anyway, I was able to assemble the hardware and circuit boards and now am getting ready to do the chassis wiring.

Figured I'd share the results thus far, just in case anyone's interested.

Cheers and Happy Holidays!