FruityPlasmid

New member

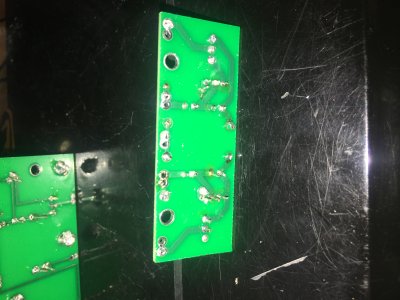

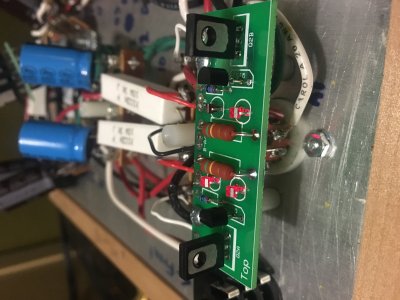

I spent a few days on and off building the Speedball, the first half went well with tests showing I didn't mess anything up, but now with the second bigger board installed the B part (D1 and D2) of the board doesn't light up, and one of the LEDs on the first smaller board, specifically D1 on the A side, doesn't light up. I need some help here, I'm not very good with this stuff